Abstract

Large-area single-crystal monolayers of two-dimensional (2D) materials such as graphene1,2,3, hexagonal boron nitride (hBN)4,5,6 and transition metal dichalcogenides7,8 have been grown. hBN is considered to be the ‘ideal’ dielectric for 2D-materials-based field-effect transistors (FETs), offering the potential for extending Moore’s law9,10. Although hBN thicker than a monolayer is more desirable as substrate for 2D semiconductors11,12, highly uniform and single-crystal multilayer hBN growth has yet to be demonstrated. Here we report the epitaxial growth of wafer-scale single-crystal trilayer hBN by a chemical vapour deposition (CVD) method. Uniformly aligned hBN islands are found to grow on single-crystal Ni (111) at early stage and finally to coalesce into a single-crystal film. Cross-sectional transmission electron microscopy (TEM) results show that a Ni23B6 interlayer is formed (during cooling) between the single-crystal hBN film and Ni substrate by boron dissolution in Ni. There are epitaxial relationships between hBN and Ni23B6 and between Ni23B6 and Ni. We also find that the hBN film acts as a protective layer that remains intact during catalytic evolution of hydrogen, suggesting continuous single-crystal hBN. This hBN transferred onto the SiO2 (300 nm)/Si wafer acts as a dielectric layer to reduce electron doping from the SiO2 substrate in MoS2 FETs. Our results demonstrate high-quality single-crystal multilayered hBN over large areas, which should open up new pathways for making it a ubiquitous substrate for 2D semiconductors.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this paper are available in the paper. Source data are available in the paper.

Code availability

All computational data are presented in the manuscript. All density functional theory calculations were performed using the Vienna Ab initio Simulation Package (VASP), which is commercially available at https://www.vasp.at/.

References

Lee, J. H. et al. Wafer-scale growth of single-crystal monolayer graphene on reusable hydrogen-terminated germanium. Science 344, 286–289 (2014).

Wu, T. R. et al. Fast growth of inch-sized single-crystalline graphene from a controlled single nucleus on Cu–Ni alloys. Nat. Mater. 15, 43–47 (2016).

Xu, X. Z. et al. Ultrafast epitaxial growth of metre-sized single-crystal graphene on industrial Cu foil. Sci. Bull. 62, 1074–1080 (2017).

Lee, J. S. et al. Wafer-scale single-crystal hexagonal boron nitride film via self-collimated grain formation. Science 362, 817–821 (2018).

Wang, L. et al. Epitaxial growth of a 100-square-centimetre single-crystal hexagonal boron nitride monolayer on copper. Nature 570, 91–95 (2019).

Chen, T. A. et al. Wafer-scale single-crystal hexagonal boron nitride monolayers on Cu (111). Nature 579, 219–223 (2020).

Yang, P. F. et al. Epitaxial growth of centimeter-scale single-crystal MoS2 monolayer on Au(111). ACS Nano 14, 5036–5045 (2020).

Choi, S. H. et al. Epitaxial single-crystal growth of transition metal dichalcogenide monolayers via the atomic sawtooth Au surface. Adv. Mater. 33, 2006601 (2021).

Li, M. Y., Su, S. K., Wong, H. S. P. & Li, L. J. How 2D semiconductors could extend Moore’s law. Nature 567, 169–170 (2019).

Dean, C. R. et al. Boron nitride substrates for high-quality graphene electronics. Nat. Nanotechnol. 5, 722–726 (2010).

Kim, S. M. et al. Synthesis of large-area multilayer hexagonal boron nitride for high material performance. Nat. Commun. 6, 8662 (2015).

Uchida, Y. et al. Controlled growth of large-area uniform multilayer hexagonal boron nitride as an effective 2D substrate. ACS Nano 12, 6236–6244 (2018).

Liu, Z. et al. Ultrathin high-temperature oxidation-resistant coatings of hexagonal boron nitride. Nat. Commun. 4, 2541 (2013).

Britnell, L. et al. Field-effect tunneling transistor based on vertical graphene heterostructures. Science 335, 947–950 (2012).

Ko, H. et al. Toward non-gas-permeable hBN film growth on smooth Fe surface. 2D Mater. 8, 034003 (2021).

Ahn, S. et al. Prevention of transition metal dichalcogenide photodegradation by encapsulation with h-BN layers. ACS Nano 10, 8973–8979 (2016).

Wang, L. et al. One-dimensional electrical contact to a two-dimensional material. Science 342, 614–617 (2013).

Shi, Y. Y. et al. Electronic synapses made of layered two-dimensional materials. Nat. Electron. 1, 458–465 (2018).

Caneva, S. et al. Controlling catalyst bulk reservoir effects for monolayer hexagonal boron nitride CVD. Nano Lett. 16, 1250–1261 (2016).

Shi, Y. M. et al. Synthesis of few-layer hexagonal boron nitride thin film by chemical vapor deposition. Nano Lett. 10, 4134–4139 (2010).

Chatterjee, S. et al. Chemical vapor deposition of boron nitride nanosheets on metallic substrates via decaborane/ammonia reactions. Chem. Mater. 23, 4414–4416 (2011).

Ismach, A. et al. Toward the controlled synthesis of hexagonal boron nitride films. ACS Nano 6, 6378–6385 (2012).

Gao, Y. et al. Repeated and controlled growth of monolayer, bilayer and few-layer hexagonal boron nitride on Pt foils. ACS Nano 7, 5199–5206 (2013).

Song, L. et al. Large scale growth and characterization of atomic hexagonal boron nitride layers. Nano Lett. 10, 3209–3215 (2010).

Kim, K. K. et al. Synthesis and characterization of hexagonal boron nitride film as a dielectric layer for graphene devices. ACS Nano 6, 8583–8590 (2012).

Jang, A. R. et al. Wafer-scale and wrinkle-free epitaxial growth of single-orientated multilayer hexagonal boron nitride on sapphire. Nano Lett. 16, 3360–3366 (2016).

Liu, D. H. et al. Conformal hexagonal-boron nitride dielectric interface for tungsten diselenide devices with improved mobility and thermal dissipation. Nat. Commun. 10, 1188 (2019).

Shi, Z. Y. et al. Vapor–liquid–solid growth of large-area multilayer hexagonal boron nitride on dielectric substrates. Nat. Commun. 11, 849 (2020).

Jin, S. et al. Colossal grain growth yields single-crystal metal foils by contact-free annealing. Science 362, 1021–1025 (2018).

Zhang, P. et al. Electroless plated Ni–Bx films as highly active electrocatalysts for hydrogen production from water over a wide pH range. Nano Energy 19, 98–107 (2016).

Rogl, P. & Schuster, J. C. Boron Nitride and Silicon Nitride Systems 79–86 (European Research Office of the U.S. Army, 1991).

Kowanda, C. & Speidel, M. O. Solubility nitrogen in liquid nickel and binary Ni–Xi alloys (Xi=Cr, Mo, W, Mn, Fe, Co) under elevated pressure. Scr. Mater. 48, 1073–1078 (2003).

Park, J. H. et al. Large-area monolayer hexagonal boron nitride on Pt foil. ACS Nano 8, 8520–8528 (2014).

Battezzati, L., Antonione, C. & Baricco, M. Undercooling of Ni-B and Fe-B alloys and their metastable phase diagrams. J. Alloys Compd. 247, 164–171 (1997).

Liu, F., Xu, J. F., Zhang, D. & Jian, Z. Y. Solidification of highly undercooled hypereutectic Ni-Ni3B alloy melt. Metall. Mater. Trans. A 45, 4810–4819 (2014).

Villars, P. & Calvert, L. D. Pearson’s Handbook of Crystallographic Data for Intermetallic Phases (ASM International, 1991).

Alem, N. et al. Atomically thin hexagonal boron nitride probed by ultrahigh-resolution transmission electron microscopy. Phys. Rev. B 80, 155425 (2009).

Caldwell, J. D. et al. Photonics with hexagonal boron nitride. Nat. Rev. Mater. 4, 552–567 (2019).

Toth, M. & Aharonovich, I. Single photon sources in atomically thin materials. Annu. Rev. Phys. Chem. 70, 123–142 (2019).

Bets, K. V., Gupta, N. & Yakobsion, B. I. How the complementarity at vicinal steps enables growth of 2D monocrystals. Nano Lett. 19, 2027–2031 (2019).

Dong, J., Zhang, L. N., Dai, X. Y. & Ding, F. The epitaxy of 2D materials growth. Nat. Commun. 11, 5862 (2020).

Zhang, L. N., Peng, P. & Ding, F. Epitaxial growth of 2D materials on high-index substrate surfaces. Adv. Funct. Mater. 31, 2100503 (2021).

Gao, J. F., Yip, J., Zhao, J. J., Yakobson, B. I. & Ding, F. Graphene nucleation on transition metal surface: structure transformation and role of the metal step edge. J. Am. Chem. Soc. 133, 5009–5015 (2011).

Yuan, Q. H., Yakobson, B. I. & Ding, F. Edge-catalyst wetting and orientation control of graphene growth by chemical vapor deposition growth. J. Phys. Chem. Lett. 5, 3093–3099 (2014).

Kim, W., Ahn, J. Y., Oh, J., Shim, J. H. & Ryu, S. Second-harmonic Young's interference in atom-thin heterocrystals. Nano Lett. 20, 8825–8831 (2020).

Kresse, G. & Furthmuller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Kresse, G. & Hafner, J. Ab initio molecular dynamics for open-shell transition metals. Phys. Rev. B 48, 13115–13118 (1993).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999).

Kappera, R. et al. Phase-engineered low-resistance contacts for ultrathin MoS2 transistors. Nat. Mater. 13, 1128–1134 (2014).

Liu, K.-K. et al. Growth of large-area and highly crystalline MoS2 thin layers on insulating substrates. Nano Lett. 12, 1538–1544 (2012).

Gorbachev, R. V. et al. Hunting for monolayer boron nitride: optical and Raman signatures. Small 7, 465–468 (2011).

Acknowledgements

This work was supported by the research fund (NRF-2019R1A4A1027934, NRF-2020R1A2C2004865, NRF-2021M3H4A1A02049651, NRF-2021R1A3B1077184 and NRF-2022R1C1C2009666) through the National Research Foundation and IBS (IBS-R-019-D1), Republic of Korea. M.C. and Y.W. acknowledge support from the Leverhulme Trust (RPG-2019-227), EPSRC (EP/T026200/1, EP/T001038/1) and Royal Society Wolfson Research Merit Award (WRM\FT\180009). European Research Council (ERC) European Union’s Horizon 2020 research and innovation programme (grant agreement no. 101019828 – 2D LOTTO).

Author information

Authors and Affiliations

Contributions

H.S.S. and K.Y.M. conceived the project. R.S.R. suggested attempting growth of hBN on Ni (111) and contributed many useful suggestions related to the growth and characterization of hBN films. K.Y.M. grew the hBN by CVD, performed the transfer of hBN and carried out SEM, electron backscatter diffraction, Raman, AFM, UV–vis and POM measurements. F.D. and L.Z. performed the theoretical calculations. S.J., M.W. and S.C. conducted the contact-free annealing of the Ni foil. S.I.Y. and H.H. carried out XPS measurements. H.H., D.S.J. and J.Y. performed electrochemical measurements. G.K. and A-.R.J. performed the H2 plasma etching. Y.W. and M.C. performed FET fabrication and analysis. H.Y.J. performed TEM, STEM and SAED pattern measurements. J.O. and S.R. performed SHG imaging experiments. H.S.S., F.D., M.C. and R.S.R. supervised this project. All authors contributed to writing of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature thanks Soo Min Kim, Lain-Jong Li and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

Extended Data Fig. 1 Growth method and annealing protocol for growth of single-crystal trilayer hBN on Ni (111).

a, Electron backscatter diffraction inverse pole figure map in the normal direction of Ni (111) foil produced by the contact-free annealing method. b, Schematic diagram of high-temperature and low-pressure CVD for the growth of hBN on Ni (111). c, Temperature–time profile for hBN growth. d, Photograph of a 2 cm × 5 cm as-grown single-crystal trilayer hBN film on Ni (111).

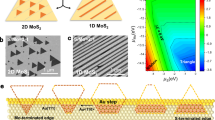

Extended Data Fig. 2 Uniformity of aligned growth of hBN flakes on Ni (111).

a, b, Large-area SEM images of as-grown unidirectionally aligned hBN flakes on Ni (111) substrate after growth for 30 min. AFM images of trilayer hBN islands for growth times of 30 min (c) and 45 min (d). The insets in c and d show height measurements taken at the position of the yellow lines. The average thicknesses of hBN islands at growth times of 30 min (total 25 flakes) and 45 min (total 17 flakes) are 1.03 ± 0.06 and 1.05 ± 0.03 nm, respectively. It suggests uniform thickness of the trilayer hBN film over large areas.

Extended Data Fig. 3 Thickness uniformity of trilayer hBN film transferred onto SiO2 (300 nm)/Si.

Photograph of 2 cm × 5 cm hBN film transferred onto the SiO2 (300 nm)/Si substrate and AFM images obtained at the eight marked positions. Insets show representative height profiles at the film edges. The mean and standard deviation of AFM thickness at 24 positions is 1.27 ± 0.06 nm.

Extended Data Fig. 4 The effect of cooling rate on hBN thickness.

AFM images of hBN film transferred onto SiO2/Si for cooling rates of −30 °C min−1 (a) and −5 °C min−1 (b) (cooling from 1,220 °C to 620 °C in both cases).

Extended Data Fig. 5 Atomic distributions, cooling rate effect and time evolution of hBN/Ni23B6/Ni.

EF-TEM mapping of hBN/Ni23B6/Ni. a, Cross-sectional TEM image (upper left) and EF-TEM maps of boron (red), nitrogen (green) and nickel (blue). b, An image of overlaid EF-TEM maps for all elements. The effect of cooling rate for cooling from 1,220 °C to 620 °C. Cross-sectional TEM images of as-formed Ni23B6 alloy for cooling rates of −60 °C min−1 (c), −30 °C min−1 (d) and −5 °C min−1 (e). f, Proposed mechanism for escape of B atoms during cooling. Slow cooling causes escape of more B atoms, and the thickness of Ni23B6 alloy decreases. g–i, schematic diagrams (upper panels) and cross-sectional TEM images (lower panels) at different growth times of 30 min (g), 45 min (h) and 60 min (i) at 1,220 °C. Cross-section TEM images show the Ni23B6 surface near the boundary of Ni23B6/Ni and Ni surface after growth for 30 min.

Extended Data Fig. 6 Growth of hBN on Ni (111) at different growth temperatures.

SEM images of hBN grown on Ni (111) for 30 min at 1,020 °C (a), 1,120 °C (b), 1,170 °C (c), 1,220 °C (d), 1,270 °C (e) and 1,320 °C (f). The average thickness of hBN islands at 1,170 °C is 1.05 ± 0.04 nm. The inset of a shows the SAED pattern of the hBN film grown at 1,020 °C.

Extended Data Fig. 7 Analysis of the crystal orientation of single-crystal trilayer and polycrystal multilayer hBN films with LC-assisted POM.

Schematic of LC alignment on hBN (a) and a corresponding photograph (b). Areas 1, 2 and 3 in b are pieces (1 cm × 1 cm) broken from a large hBN film (2 cm × 5 cm) on SiO2 (300 nm)/Si. c, Representative POM images of LC-coated hBN film as a function of the polarized light angles from 0 to 180° at Area 1 in b. POM images of Areas 2 and 3 are the same as Area 1. d, POM images of LC-coated polycrystal hBN film as a function of the polarized light angles from 0 to 180°. The inhomogeneous colour contrast is shown as a function of the polarized light angles.

Extended Data Fig. 8 Analysis of crystalline domains with polarized SHG imaging and PL spectra.

Optical micrographs of ‘single-crystal’ trilayer hBN (a) and polycrystalline multilayer hBN (b) films. Raster scanning images of SHG intensity ratio, (Icross/Ipara)0.5, which is governed by the crystallographic orientation: single-crystal trilayer hBN (c) and polycrystalline multilayer hBN (d) films. Ipara and Icross denote the SHG signals parallel and perpendicular to the polarization of the fundamental 950-nm beam, respectively. The images were obtained within the blue squares of a and b. Histograms in e and f show the ratio distribution of c and d, respectively. A single domain could be inferred in e, whereas four grains in f. Note that the centre-to-centre distance in trilayer hBN islands in Fig. 1 and Extended Data Fig. 2 is less than 20 μm. The results indicate that the trilayer hBN sample in a is a single crystal and, thus, does not have any grain boundaries, unlike the polycrystalline hBN sample in b. g, PL spectra of single-crystal trilayer and polycrystalline hBN (h) films on SiO2 (300 nm)/Si substrate. Spectra were measured at ten different positions for each sample and all of them showed essentially the same result. The excitation wavelength is 340 nm (140 fs 80 MHz, 1.3 mW). Although the PL emission of polycrystalline hBN appears at 565 nm (about 2.19 eV), that of single-crystal trilayer hBN film is the same as from the SiO2 (300 nm)/Si substrate.

Extended Data Fig. 9 Growth and characterizations of bilayer and five-layer hBN films.

a, Photograph of 5 mm × 5 mm bilayer hBN film on a SiO2 (300 nm)/Si substrate after transfer. b, Raman spectra at the 16 positions indicated in a. c, Comparison of Raman spectra of bilayer and trilayer hBN. The absolute Raman intensity of bilayer hBN (197.1 ± 17.4) is 1.6 times lower than that of trilayer hBN (314.4 ± 23.5). This is consistent with the results reported for the ratio of Raman peak intensities for mechanically exfoliated trilayer and bilayer hBN (ref. 52). d, AFM images show four edges of the bilayer hBN film transferred onto the SiO2 (300 nm)/Si substrate. Representative height profiles are shown in the insets. The average AFM thickness at 12 positions is 0.91 ± 0.04 nm. e, POM images of LC-coated bilayer hBN film as a function of the polarized light angle (from 0 to 180°). f, Photograph of 5 mm × 5 mm five-layer hBN film on a SiO2 (300 nm)/Si substrate after transfer. g, Raman spectra at the 16 positions indicated in f. h, Comparison of Raman spectra of trilayer and five-layer hBN. The absolute Raman intensity of five-layer hBN (515.6 ± 24.1) is 1.64 times higher than that of trilayer hBN (314.4 ± 23.5). This is consistent with the result for the ratio of Raman peak intensities for mechanically exfoliated five-layer and trilayer hBN (ref. 52). i, AFM images show four edges of the five-layer hBN film transferred onto the SiO2 (300 nm)/Si substrate. Representative height profiles are shown in the insets. The average AFM thickness at 12 positions is 1.93 ± 0.11 nm. j, POM images of LC-coated five-layer hBN film as a function of the polarized light angle (from 0 to 180°). As we demonstrated above, we could control the thickness of hBN film with different calculated specific binding energies by changing flows of reactant gases, which affects chemical equilibrium and chemical potential. Our standard condition leads to commonly observed single-crystal 3L hBN in a broad range of borazine gas flow rates, and we need to substantially change the amount of borazine or to add another precursor, N2, as a feedstock to change the chemical equilibrium to tune the hBN thickness. Finally, we found bilayer hBN when borazine gas flow was reduced from 0.1 sccm to 0.025 sccm. hBN thicker than trilayer was observed when large N2 gas flow (50 sccm) was added.

Extended Data Fig. 10 Configurations of a hBN nucleus (N7B6) at different sites of vicinal Ni (111) substrates.

The calculated binding energies are shown below with a unit of eV.

Supplementary information

Rights and permissions

About this article

Cite this article

Ma, K.Y., Zhang, L., Jin, S. et al. Epitaxial single-crystal hexagonal boron nitride multilayers on Ni (111). Nature 606, 88–93 (2022). https://doi.org/10.1038/s41586-022-04745-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-022-04745-7

This article is cited by

-

Ultraflat Cu(111) foils by surface acoustic wave-assisted annealing

Nature Communications (2024)

-

Realization of large-area ultraflat chiral blue phosphorene

Nature Communications (2024)

-

Single-crystal hBN Monolayers from Aligned Hexagonal Islands

Nature Communications (2024)

-

Ultraflat single-crystal hexagonal boron nitride for wafer-scale integration of a 2D-compatible high-κ metal gate

Nature Materials (2024)

-

Phase-engineered synthesis of atomically thin te single crystals with high on-state currents

Nature Communications (2024)