Abstract

The ability of superhydrophobic surfaces to stay dry, self-clean and avoid biofouling is attractive for applications in biotechnology, medicine and heat transfer1,2,3,4,5,6,7,8,9,10. Water droplets that contact these surfaces must have large apparent contact angles (greater than 150 degrees) and small roll-off angles (less than 10 degrees). This can be realized for surfaces that have low-surface-energy chemistry and micro- or nanoscale surface roughness, minimizing contact between the liquid and the solid surface11,12,13,14,15,16,17. However, rough surfaces—for which only a small fraction of the overall area is in contact with the liquid—experience high local pressures under mechanical load, making them fragile and highly susceptible to abrasion18. Additionally, abrasion exposes underlying materials and may change the local nature of the surface from hydrophobic to hydrophilic19, resulting in the pinning of water droplets to the surface. It has therefore been assumed that mechanical robustness and water repellency are mutually exclusive surface properties. Here we show that robust superhydrophobicity can be realized by structuring surfaces at two different length scales, with a nanostructure design to provide water repellency and a microstructure design to provide durability. The microstructure is an interconnected surface frame containing ‘pockets’ that house highly water-repellent and mechanically fragile nanostructures. This surface frame acts as ‘armour’, preventing the removal of the nanostructures by abradants that are larger than the frame size. We apply this strategy to various substrates—including silicon, ceramic, metal and transparent glass—and show that the water repellency of the resulting superhydrophobic surfaces is preserved even after abrasion by sandpaper and by a sharp steel blade. We suggest that this transparent, mechanically robust, self-cleaning glass could help to negate the dust-contamination issue that leads to a loss of efficiency in solar cells. Our design strategy could also guide the development of other materials that need to retain effective self-cleaning, anti-fouling or heat-transfer abilities in harsh operating environments.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Wong, T.-S., Sun, T., Feng, L. & Aizenberg, J. Interfacial materials with special wettability. MRS Bull. 38, 366–371 (2013).

Liu, M., Wang, S. & Jiang, L. Nature-inspired superwettability systems. Nat. Rev. Mater. 2, 17036 (2017).

Bhushan, B. & Jung, Y. C. Natural and biomimetic artificial surfaces for superhydrophobicity, self-cleaning, low adhesion, and drag reduction. Prog. Mater. Sci. 56, 1–108 (2011).

Schmidt, D. L., Brady, R. F., Jr, Lam, K., Schmidt, D. C. & Chaudhury, M. K. Contact angle hysteresis, adhesion, and marine biofouling. Langmuir 20, 2830–2836 (2004).

Jung, S., Tiwari, M. K., Doan, N. V. & Poulikakos, D. Mechanism of supercooled droplet freezing on surfaces. Nat. Commun. 3, 615 (2012).

Bahng, J. H. et al. Anomalous dispersions of ‘hedgehog’ particles. Nature 517, 596–599 (2015).

Rastogi, V. et al. Synthesis of light-diffracting assemblies from microspheres and nanoparticles in droplets on a superhydrophobic surface. Adv. Mater. 20, 4263–4268 (2008).

Lee, S. Y., Rahmawan, Y. & Yang, S. Transparent and superamphiphobic surfaces from mushroom-like micropillar arrays. ACS Appl. Mater. Interfaces 7, 24197–24203 (2015).

Miljkovic, N. & Wang, E. N. Condensation heat transfer on superhydrophobic surfaces. MRS Bull. 38, 397–406 (2013).

Pan, S. et al. Coatings super-repellent to ultralow surface tension liquids. Nat. Mater. 17, 1040–1047 (2018).

Gao, L. & McCarthy, T. J. The “lotus effect” explained: two reasons why two length scales of topography are important. Langmuir 22, 2966–2967 (2006).

Tuteja, A. et al. Designing superoleophobic surfaces. Science 318, 1618–1622 (2007).

Quéré, D. Wetting and roughness. Annu. Rev. Mater. Res. 38, 71–99 (2008).

Butt, H.-J. et al. Characterization of super liquid-repellent surfaces. Curr. Opin. Colloid Interface Sci. 19, 343–354 (2014).

Liu, T. L. & Kim, C. J. Turning a surface superrepellent even to completely wetting liquids. Science 346, 1096–1100 (2014).

Sbragaglia, M. et al. Spontaneous breakdown of superhydrophobicity. Phys. Rev. Lett. 99, 156001 (2007).

Herminghaus, S. Roughness-induced non-wetting. Europhys. Lett. 52, 165 (2000).

Tian, X., Verho, T. & Ras, R. H. A. Moving superhydrophobic surfaces toward real-world applications. Science 352, 142–143 (2016).

Milionis, A., Loth, E. & Bayer, I. S. Recent advances in the mechanical durability of superhydrophobic materials. Adv. Colloid Interface Sci. 229, 57–79 (2016).

Bhushan, B. & Nosonovsky, M. Scale effects in friction using strain gradient plasticity and dislocation-assisted sliding (microslip). Acta Mater. 51, 4331–4345 (2003).

Zhang, W. et al. Facile design and fabrication of superwetting surfaces with excellent wear-resistance. ACS Appl. Mater. Interfaces 9, 15776–15784 (2017).

Lu, Y. et al. Repellent materials. Robust self-cleaning surfaces that function when exposed to either air or oil. Science 347, 1132–1135 (2015).

Zimmermann, J., Reifler, F. A., Fortunato, G., Gerhardt, L.-C. & Seeger, S. A simple, one-step approach to durable and robust superhydrophobic textiles. Adv. Funct. Mater. 18, 3662–3669 (2008).

Azimi, G., Dhiman, R., Kwon, H. M., Paxson, A. T. & Varanasi, K. K. Hydrophobicity of rare-earth oxide ceramics. Nat. Mater. 12, 315–320 (2013).

Kondrashov, V. & Rühe, J. Microcones and nanograss: toward mechanically robust superhydrophobic surfaces. Langmuir 30, 4342–4350 (2014).

Zhang, Y., Ge, D. & Yang, S. Spray-coating of superhydrophobic aluminum alloys with enhanced mechanical robustness. J. Colloid Interface Sci. 423, 101–107 (2014).

Peng, C., Chen, Z. & Tiwari, M. K. All-organic superhydrophobic coatings with mechanochemical robustness and liquid impalement resistance. Nat. Mater. 17, 355–360 (2018).

Jin, H., Tian, X., Ikkala, O. & Ras, R. H. A. Preservation of superhydrophobic and superoleophobic properties upon wear damage. ACS Appl. Mater. Interfaces 5, 485–488 (2013).

Deng, X., Mammen, L., Butt, H.-J. & Vollmer, D. Candle soot as a template for a transparent robust superamphiphobic coating. Science 335, 67–70 (2012).

Bergin, M. H., Ghoroi, C., Dixit, D., Schauer, J. J. & Shindell, D. T. Large reductions in solar energy production due to dust and particulate air pollution. Environ. Sci. Technol. Lett. 4, 339–344 (2017).

Liimatainen, V. et al. Mapping microscale wetting variations on biological and synthetic water-repellent surfaces. Nat. Commun. 8, 1798 (2017).

Song, J., Xu, W. & Lu, Y. One-step electrochemical machining of superhydrophobic surfaces on aluminum substrates. J. Mater. Sci. 47, 162–168 (2011).

Gao, X., Tong, W., Ouyang, X. & Wang, X. Facile fabrication of a superhydrophobic titanium surface with mechanical durability by chemical etching. RSC Adv. 5, 84666–84672 (2015).

Song, J., Huang, W., Liu, J., Huang, L. & Lu, Y. Electrochemical machining of superhydrophobic surfaces on mold steel substrates. Surf. Coat. Technol. 344, 499–506 (2018).

Yao, X. et al. Bioinspired ribbed nanoneedles with robust superhydrophobicity. Adv. Funct. Mater. 20, 656–662 (2010).

Xu, W., Song, J., Sun, J., Lu, Y. & Yu, Z. Rapid fabrication of large-area, corrosion-resistant superhydrophobic Mg alloy surfaces. ACS Appl. Mater. Interfaces 3, 4404–4414 (2011).

Miljkovic, N., Preston, D. J., Enright, R. & Wang, E. N. Electrostatic charging of jumping droplets. Nat. Commun. 4, 2517 (2013).

Wang, N., Xiong, D., Deng, Y., Shi, Y. & Wang, K. Mechanically robust superhydrophobic steel surface with anti-icing, UV-durability, and corrosion resistance properties. ACS Appl. Mater. Interfaces 7, 6260–6272 (2015).

Sun, J. et al. Electrochemical fabrication of superhydrophobic Zn surfaces. Appl. Surf. Sci. 315, 346–352 (2014).

Hosono, E., Fujihara, S., Honma, I. & Zhou, H. Superhydrophobic perpendicular nanopin film by the bottom-up process. J. Am. Chem. Soc. 127, 13458–13459 (2005).

Luo, Y. et al. Design and fabrication of a tip-like ZnO nanotube array structure with condensate microdrop self-propelling function. ChemNanoMat 2, 1018–1022 (2016).

Su, F. & Yao, K. Facile fabrication of superhydrophobic surface with excellent mechanical abrasion and corrosion resistance on copper substrate by a novel method. ACS Appl. Mater. Interfaces 6, 8762–8770 (2014).

Acknowledgements

We thank B. J. Yu, J. L. Yang, Y. Li. and G.W. Zhou for discussions, and J. L. Song for providing the samples of the conventional superhydrophobic surfaces. This work was supported by the National Natural Science Foundation of China (21603026), the European Research Council ERC-2016-CoG (725513-SuperRepel), the Academy of Finland (Centres of Excellence Programme 2014–2019), Aalto University AScI/ELEC Thematic Research Programme, Business Finland Project TUTL-SDAM (6798/31/2017) and the University Research Council Grant (CityU9/CRF/13G).

Author information

Authors and Affiliations

Contributions

D.W. and X.D. conceived the research and designed the experiments. X.D. and R.H.A.R. supervised the research. D.W., Q.S., M.J.H., C.Z., F.-Y.L., T.Z. and Q.C. carried out the experiments. Q.L., S.-P.Z., Z.W., L.C., Q.Z. and B.H. built the analytical models. All authors analysed and interpreted the data and wrote the paper.

Corresponding authors

Ethics declarations

Competing interests

X.D., D.W. and R.H.A.R. are inventors on a patent application relating to the surfaces described in this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

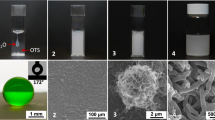

Extended Data Fig. 1 Scanning droplet adhesion microscopy.

a, Droplet adhesion force curve recorded during scanning droplet adhesion microscopy31 sampling of the superhydrophobic surface. Before making contact with the surface, the droplet is freely suspended from the disc (I). After contact is established, the force begins to increase steeply, indicating that the droplet is being pushed against the surface (II). After the peak force, the stage is retracted; the force becomes negative as the liquid meniscus is elongated (III). Ultimately, the droplet detaches from the test surface, which induces a brief period of oscillations (IV). The pull-off force is defined as the difference between the baseline force after detachment and the global minimum of the curve (V). b, Pull-off forces for water drops on superhydrophobic surfaces, before and after abrasion, as a function of f micro. Pull-off forces were recorded from an area of 2.0 mm × 2.0 mm, with 500-μm spacing between each measurement point. Data are mean ± s.d. from 25 independent measurements.

Extended Data Fig. 2 The impact of liquid jets on the hydrophobic surface.

a, Deflection of water jets from the superhydrophobic surface before (left) and after (right) abrasion. b, The change of angle (Δα) when water jets (at a flow rate of approximately 6 ml min−1) are deflected by the superhydrophobic surfaces before and after abrasion. Δα = αincident − αdeflected; Δα is plotted as a function of f micro. Inverted-pyramidal structures (w + l = 60 μm) on silicon substrates were used for this experiment. Data are mean ± s.d. from at least five independent measurements.

Extended Data Fig. 3 The impact of water droplets on the hydrophobic surface.

Energy dissipation of the water drops (5.5 μl, 14.0 mm of height) after impact on the armoured superhydrophobic surfaces before and after abrasion, plotted as a function of f micro. Inverted-pyramidal microstructures (w + l = 60 μm) on silicon substrates were used for this experiment. Data are mean ± s.d. from at least five independent measurements.

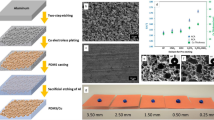

Extended Data Fig. 4 Comparison of the mechanical stability of various superhydrophobic surfaces.

Symbols of the same colour area indicate superhydrophobic surfaces with mechanical stabilities of the same order of magnitude. The x axis represents the resistance to linear abrasion by polypropylene with a normal load (3 N), the y axis represents the resistance to scratching by an alloy tip with specified normal load. Each data point represents the capacity of the corresponding surface to maintain its superhydrophobicity under the above applied conditions. All samples, including those ones received from collaborators, were abraded in the same setup under similar conditions. Data are mean ± s.d. from at least nine independent measurements. See refs. 29,32,33,34,35,36,37,38,39,40,41,42.

Extended Data Fig. 5 Self-cleaning of the surface in fog.

The optical image sequences show the self-cleaning of the armoured superhydrophobic surface in fog. The red arrows indicate the dust particles (collected from air in Chengdu, China) on the surface. The yellow circle highlights how the droplet captures the dust particle and rolls off of the surface. The images were recorded with a Photron SA5 high-speed camera fitted with a macro lens at a frame rate of 5,000 frames per second. The surface was placed on an aluminium alloy cold plate with a tilt angle of approximately 45°. The cold plate was controlled at around 2 °C, and the fog was at an ambient temperature with a high relative humidity of around 95%. The fog consisted of a cloud of water droplets (average radius 3.5 μm) suspended in air, generated using an ultrasonic humidifier.

Extended Data Fig. 6 Dust removal by self-cleaning.

a, Illustration showing the self-cleaning of the armoured superhydrophobic surface in fog. b, c, Sequences of photographs show the condensation of fog on a dust-polluted planar silicon wafer (b) and on the dust-polluted armoured superhydrophobic surface (c). The dust was collected from air in Chengdu, China.

Supplementary information

Supplementary Information

The supplementary information includes supplementary methods, supplementary discussion, supplementary figures, supplementary table and supplementary references.

Supplementary Video 1: Mechanical robustness test of conventional superhydrophobic surfaces.

Conventional superhydrophobic surfaces are easily damaged. The abrasion object is a steel knife. The video was replayed at original speed. The original audio in this video has been retained. (QuickTime).

Supplementary Video 2: Mechanical robustness test of silicon and curved ceramic armoured superhydrophobic surfaces.

Armored superhydrophobic surfaces can stand harsh conditions of mechanical abrasion. The abrasion objects include a steel knife, screwdriver, polymer (PP), finger and sandpaper (NIKKEN P800, Nihon Kenshi Co., Ltd.). The load forces were measured with a force sensor. The video was replayed at original speed. The original audio in this video has been retained. (QuickTime).

Supplementary Video 3: The mechanical robustness test of the large size plain ceramic armoured superhydrophobic surface.

The abrasion objects include a steel knife, screwdriver, steel wool, sandpaper (NIKKEN P800, Nihon Kenshi Co., Ltd.) and metal brush. The video was replayed at original speed. The original audio in this video has been retained. (QuickTime).

Supplementary Video 4: Water drop impact on the armoured superhydrophobic surfaces before and after abrasion.

It was performed by releasing individual water drops (volume 5.5 μl) from a height of 14 mm to enable gravity-induced acceleration of the drops. Videos were filmed at 10,000 fps and replayed at 30 fps. (QuickTime)

Supplementary Video 5: Long-term mechanical durability test of the armored superhydrophobic surfaces by repeated linear abrasion measurements.

For the measurement, the load is approximately 3 N (12 MPa) and the horizontal velocity of the platform is 50 mm min-1 controlled by software. The video was replayed at original speed. (QuickTime).

Supplementary Video 6: High-speed jet impact test on the armoured superhydrophobic surface.

The test was conducted under constant pressure (∼1.4 MPa) and Δt = 800 ms, 128 ml water was jetted out of the nozzle. This is equivalent to an average jet speed of 32.6 m s-1 (We ∼ 36,478). The video was replayed at original speed. The original audio in this video has been retained. (QuickTime).

Supplementary Video 7: Mechanical robustness test of glass armored superhydrophobic surfaces.

Armored superhydrophobic glass surfaces can stand harsh conditions of mechanical abrasion. The abrasion objects include a steel knife, polymer (PP). The video was replayed at original speed. The original audio in this video has been retained. (QuickTime).

Rights and permissions

About this article

Cite this article

Wang, D., Sun, Q., Hokkanen, M.J. et al. Design of robust superhydrophobic surfaces. Nature 582, 55–59 (2020). https://doi.org/10.1038/s41586-020-2331-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-020-2331-8

This article is cited by

-

Challenges to materials for local glacier conservation

Nature Water (2025)

-

Control of surface structure and properties by side chain effects of polymers

Polymer Journal (2025)

-

Deformation resistant monolithic hierarchical textures inducing stretchable superamphiphobicity with environmental adaptability and flame retardancy

Nature Communications (2025)

-

Aluminium surface work hardening enables multi-scale 3D lithography

Nature Materials (2025)

-

Bioinspired Ultrasensitive Flexible Strain Sensors for Real-Time Wireless Detection of Liquid Leakage

Nano-Micro Letters (2025)