Abstract

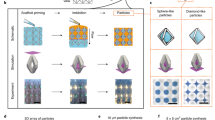

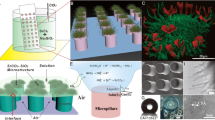

Developing adaptive materials with geometries that change in response to external stimuli provides fundamental insights into the links between the physical forces involved and the resultant morphologies and creates a foundation for technologically relevant dynamic systems1,2. In particular, reconfigurable surface topography as a means to control interfacial properties3 has recently been explored using responsive gels4, shape-memory polymers5, liquid crystals6,7,8 and hybrid composites9,10,11,12,13,14, including magnetically active slippery surfaces12,13,14. However, these designs exhibit a limited range of topographical changes and thus a restricted scope of function. Here we introduce a hierarchical magneto-responsive composite surface, made by infiltrating a ferrofluid into a microstructured matrix (termed ferrofluid-containing liquid-infused porous surfaces, or FLIPS). We demonstrate various topographical reconfigurations at multiple length scales and a broad range of associated emergent behaviours. An applied magnetic-field gradient induces the movement of magnetic nanoparticles suspended in the ferrofluid, which leads to microscale flow of the ferrofluid first above and then within the microstructured surface. This redistribution changes the initially smooth surface of the ferrofluid (which is immobilized by the porous matrix through capillary forces) into various multiscale hierarchical topographies shaped by the size, arrangement and orientation of the confining microstructures in the magnetic field. We analyse the spatial and temporal dynamics of these reconfigurations theoretically and experimentally as a function of the balance between capillary and magnetic pressures15,16,17,18,19 and of the geometric anisotropy of the FLIPS system. Several interesting functions at three different length scales are demonstrated: self-assembly of colloidal particles at the micrometre scale; regulated flow of liquid droplets at the millimetre scale; and switchable adhesion and friction, liquid pumping and removal of biofilms at the centimetre scale. We envision that FLIPS could be used as part of integrated control systems for the manipulation and transport of matter, thermal management, microfluidics and fouling-release materials.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Change history

09 July 2018

Corrected online 9 July 2018 The Supplementary Video files were labelled incorrectly. This has now been corrected online.

References

Vaia, R. & Baur, J. Adaptive composites. Science 319, 420–421 (2008).

Kuroki, H., Tokarev, I. & Minko, S. Responsive surfaces for life science applications. Annu. Rev. Mater. Res. 42, 343–372 (2012).

Xia, F. & Jiang, L. Bio-inspired, smart, multiscale interfacial materials. Adv. Mater. 20, 2842–2858 (2008).

Yoshida, R. Self-oscillating gels driven by the Belousov–Zhabotinsky reaction as novel smart materials. Adv. Mater. 22, 3463–3483 (2010).

Reddy, S., Arzt, E. & del Campo, A. Bioinspired surfaces with switchable adhesion. Adv. Mater. 19, 3833–3837 (2007).

van Oosten, C. L., Bastiaansen, C. W. M. & Broer, D. J. Printed artificial cilia from liquid-crystal network actuators modularly driven by light. Nat. Mater. 8, 677–682 (2009).

Liu, D., Liu, L., Onck, P. R. & Broer, D. J. Reverse switching of surface roughness in a self-organized polydomain liquid crystal coating. Proc. Natl Acad. Sci. USA 112, 3880–3885 (2015).

Liu, D. & Broer, D. J. New insights into photoactivated volume generation boost surface morphing in liquid crystal coatings. Nat. Commun. 6, 8334 (2015).

Sidorenko, A., Krupenkin, T., Taylor, A., Fratzl, P. & Aizenberg, J. Reversible switching of hydrogel-actuated nanostructures into complex micropatterns. Science 315, 487–490 (2007).

He, X. M. et al. Synthetic homeostatic materials with chemo-mechano-chemical self-regulation. Nature 487, 214–218 (2012).

Aizenberg, J., Hatton, B., Yao, X., Aizenberg, M. & Wang, W. Dynamic and switchable slippery surfaces. US patent 9,683,197 (2017).

Khalil, K. S., Mahmoudi, S. R., Abu-dheir, N. & Varanasi, K. K. Active surfaces: Ferrofluid-impregnated surfaces for active manipulation of droplets. Appl. Phys. Lett. 105, 0416604 (2014).

Tian, D. et al. Fast responsive and controllable liquid transport on a magnetic fluid/nanoarray composite interface. ACS Nano 10, 6220–6226 (2016).

Irajizad, P., Hasnain, M., Farokhnia, N., Sajadi, S. M. & Ghasemi, H. Magnetic slippery extreme icephobic surfaces. Nat. Commun. 7, 13395 (2016).

Rosensweig, R. E. Ferrohydrodynamics (Dover Publications, Mineola, 1997).

Rosensweig, R. E. Magnetic Fluids. Sci. Am. 247, 136–145 (1982).

Odenbach, S. (ed) Lecture Notes in Physics: Colloidal Magnetic Fluids: Basics, Development and Application of Ferrofluids (Springer, Berlin, 2009).

Timonen, J. V. I., Latikka, M., Leibler, L., Ras, R. H. A. & Ikkala, O. Switchable static and dynamic self-assembly of magnetic droplets on superhydrophobic surfaces. Science 341, 253–257 (2013).

Torres-Díaz, I. & Rinaldi, C. Recent progress in ferrofluids research: novel applications of magnetically controllable and tunable fluids. Soft Matter 10, 8584–8602 (2014).

Timonen, J. V. I., Demirörs, A. F. & Grzybowski, B. A. Magnetofluidic tweezing of nonmagnetic colloids. Adv. Mater. 28, 3453–3459 (2016).

Yao, X. et al. Adaptive fluid-infused porous films with tunable transparency and wettability. Nat. Mater. 12, 529–534 (2013).

Schellenberger, F. et al. Direct observation of drops on slippery lubricant-infused surfaces. Soft Matter 11, 7617–7626 (2015).

Parsegian, V. A. Van der Waals Forces: a Handbook for Biologists, Chemists, Engineers, and Physicists (Cambridge Univ. Press, Cambridge, 2006).

Israelachvili, J. N. Intermolecular and Surface Forces 3rd edn, Ch. 13 (Academic Press, Burlington, 2011).

Reiter, G. et al. Thin film instability induced by long-range forces. Langmuir 15, 2551–2558 (1999).

Daniel, D., Timonen, J. V. I., Li, R., Velling, S. J. & Aizenberg, J. Oleoplaning droplets on lubricated surfaces. Nat. Phys. 13, 1020–1025 (2017).

Hatch, A., Kamholz, A. E., Holman, G., Yager, P. & Bohringer, K. F. A ferrofluidic magnetic micropump. J. Microelectromech. Syst. 10, 215–221 (2001).

Grinthal, A. & Aizenberg, J. Adaptive all the way down: building responsive materials from hierarchies of chemomechanical feedback. Chem. Soc. Rev. 42, 7072–7085 (2013).

McKeon, B. J., Sharma, A. S. & Jacobi, I. Experimental manipulation of wall turbulence: A systems approach. Phys. Fluids 25, 031301 (2013).

Park, K.-C. et al. Condensation on slippery asymmetric bumps. Nature 531, 78–82 (2016).

Pamme, N. Magnetism and microfluidics. Lab Chip 6, 24–38 (2006).

Verho, T. et al. Reversible switching between superhydrophobic states on a hierarchically structured surface. Proc. Natl Acad. Sci. USA 109, 10210–10213 (2012).

Epstein, A. K., Wong, T. S., Belisle, R. A., Boggs, E. M. & Aizenberg, J. Liquid-infused structured surfaces with exceptional anti-biofouling performance. Proc. Natl Acad. Sci. USA 109, 13182–13187 (2012).

Sutton, A. et al. Photothermally triggered actuation of hybrid materials as a new platform for in vitro cell manipulation. Nat. Commun. 8, 14700 (2017).

Pokroy, B., Epstein, A. K., Persson-Gulda, M. C. M. & Aizenberg, J. Fabrication of bioinspired actuated nanostructures with arbitrary geometry and stiffness. Adv. Mater. 21, 463–469 (2009).

Kim, P., Adorno-Martinez, W. E., Khan, M. & Aizenberg, J. Enriching libraries of high-aspect-ratio micro- or nanostructures by rapid, low-cost, benchtop nanofabrication. Nat. Protocols 7, 311–327 (2012).

Acheson, D. J. Elementary Fluid Dynamics Ch. 7 (Oxford Univ. Press, New York, 1990).

de Gennes, P.-G., Brochard-Wyart, F. & Quéré, D. Capillarity and Wetting Phenomena: Drops, Bubbles, Pearls, Waves Ch. 4 (Springer, Berlin, 2004).

Hardy, W. B. The tension of composite fluid surfaces and the mechanical stability of films of fluid. Proc. R. Soc. Lond. A 86, 610–635 (1912).

Hardy, W. B. The tension of composite fluid surfaces.—No. II. Proc. R. Soc. Lond. A 88, 313–333 (1913).

Smith, J. D. et al. Droplet mobility on lubricant-impregnated surfaces. Soft Matter 9, 1772–1780 (2013).

Bonn, D., Eggers, J., Indekeu, J., Meunier, J. & Rolley, E. Wetting and spreading. Rev. Mod. Phys. 81, 739–805 (2009).

Fowkes, F. M. Attractive forces at interfaces. Ind. Eng. Chem. 56, 40–52 (1964).

Acknowledgements

This work is supported by DOE under award number DE-SC0005247 (experiment) and by the NSF under award number DMREF-1533985 (theory). This work was performed in part at the Center for Nanoscale Systems at Harvard University (CNS), which is supported by the NSF under award number ECS-0335765. We thank J. C. Weaver for assistance with 3D printing, M. Khan for assistance with preparing micro-textured silicon master, P. Kim and J. Alvarenga for assistance with force measurements, K. Davey at American Electromechanics for assistance with designing the electromagnet, and N. Vogel, I. Morrison, Y. Hu, P. Kim, D. Daniel, M. Kreder and O. Ahanotu for discussions. W.W. thanks the Humboldt foundation for a fellowship. J.V.I.T. was supported by the European Commission through the Seventh Framework Programme (FP7) project DynaSLIPS (project number 626954). D.-M.D., M.S. and W.W. are supported by the Max Planck Society.

Author information

Authors and Affiliations

Contributions

J.A., W.W. and J.V.I.T. designed the experiments. W.W. performed the experiments on the dynamics of micro-topography, droplet manipulation, pumping and wrapping-layer-related calculations. J.V.I.T. performed experiments with magnet arrays and manipulation of colloids. C.T.Z. fabricated the microstructures. D.-M.D. measured the ferrofluid overlayer thickness. D.-M.D., M.S. and W.W. performed the adhesion and friction measurements. S.Ko. and J.V.I.T. performed the biofilm experiments. L.M., A.C., W.W. and J.V.I.T. performed the scaling analysis. A.G. assisted in the design of experiments. S.Ke. and J.C. assisted in droplet experiments. R.T.B. assisted in the pump design. T.-S.W., B.H. and S.H.K. contributed to the initial conception of the project. J.A., W.W., J.V.I.T., A.G. and A.C. wrote the manuscript. J.A. supervised the research.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

Extended Data Fig. 1 Microstructure geometries and techniques for studying the dynamics of the topographical responses of FLIPS.

a, Microstructure geometries used in the scaling analysis of the dynamics of micro-topographical response: arrays of microchannels (1–3) and an array of microplates (4). The comparisons between 1 and 2–4 show the influence of h0, dy and dx, respectively. b, Angled illumination technique to highlight the micro-topographical region. A cold LED line light (Zeiss CL 6000 and line light S) illuminates the FLIPS sample from an incidence angle of about 30° to induce scattering from the micro-topographical region. The contrast due to the high brightness produced from the scattering facilitates the colour thresholding step in the video processing. The two images on the right show a comparison with and without the LED. c, Force-probe technique to measure the thickness of the ferrofluid overlayer. The diagram on the left is a schematic of the set-up. A spherical probe connected to a load cell is lowered slowly onto the FLIPS surface through the motion of a piezo stage. The speed of the approach (10 μm s−1) and the sampling rate of the load cell (1 ms) determine the limit of the measurement resolution (10 nm). The plot on the right is a representative force–displacement curve from the measurement. The overlayer thickness is the distance between the capillary snap-in (the moment the probe touches the top of the overlayer) and the beginning of the steep increase in the force (the moment the probe touches the top of the microstructures).

Extended Data Fig. 2 Profiles of ferrofluid–air interfaces measured by a 3D laser-scanning confocal microscope, the dependence of the scaling relations on the overlayer thickness, and draining ferrofluid along a curved path.

a, 3D profiles of the ferrofluid–air interface measured along the x axis at various distances from the edge of the magnet (labelled). The profiles show a gradual increase in the ferrofluid level inside the channel along the x axis, which corresponds to a gradual decrease in interfacial curvature. Measurements were performed on a 1 inch × 3 inch FLIPS sample after 2 h. Pattern 1 was used, and the channel direction was aligned to the long side of the FLIPS sample. On the right is a plot of the cross-sectional profiles of the ferrofluid–air interface. The signal is noisy in the high-curvature region near the edge, owing to the limit of the numerical aperture of the 100× long-working-distance objective used. b, 3D profiles of ferrofluid–air interface measured 1.5 cm away from the edge of the magnet over time (labelled). The FLIPS sample is the same as in a. The profiles show a gradual decrease in ferrofluid level inside the channel, which corresponds to a gradual increase in interfacial curvature. The corresponding plots of the cross-sectional profiles are presented in Fig. 1c. c, Dependence of the scaling relations on the overlayer thickness. Pattern 2 was used. Increasing the overlayer thickness decreases the prefactor but increases the power in the scaling relations. d, Effects of varying h0, dy and dx on the scaling relations. The overlayer thicknesses are roughly 10–20 μm. e, Draining of ferrofluid along a curved path in a spiral pattern, demonstrating the ability of the porous-capillary flow to make turns.

Extended Data Fig. 3 Simulation of magnetic pressure and fine-tuning of the balance between magnetic and capillary pressure to create or conceal the micro-topography of FLIPS.

a, Simulated magnetic field B = μ0H0 in free space surrounding a 0.5-inch-tall and 0.5-inch-diameter NdFeB magnet. b, Magnetization curve of ferrofluid 1 (from Ferrotec). The ferrofluid rapidly reaches its saturation magnetization μ0Ms ≈ 0.04 T. The saturation magnetization is regarded as a linear function of ferrofluid concentration in the following estimate. c, Magnetic pressure of ferrofluid 1 in the region above the magnet. The magnetic pressure (in kPa) can be considered as the magnetic energy density (in kJ m−3). Ferrofluid flows from a high pressure (energy) region to a low pressure (energy) region. d, Turning on the micro-topographical response; |pm| ≈ 104 Pa > 103 Pa ≈ pγ. e–g, Turning off the micro-topographical response. e, Response when the ferrofluid is diluted to 4% by volume; |pm| ≈ 102 Pa < 103 Pa ≈ pγ. f, Response using a weaker magnet (Alnico); |pm| ≈ 103 Pa ≈ 103 Pa ≈ pγ. g, The distance between the repeating units of the microstructure is reduced so that the capillary pressure increases; |pm| ≈ 104 Pa ≈ 104 Pa ≈ pγ. The microstructure is pattern 5, which is a hexagonal array of posts of 1.5 μm in diameter and about 10 μm in height. The spacing between posts is 1.4 μm. The bottom panels in d–g show the corresponding 3D profiles of the ferrofluid–air interface near the magnet. Only in d is the interface pulled down towards the bottom of the microstructure.

Extended Data Fig. 4 Wrapping layers around a water droplet in air and in a hydrocarbon on FLIPS, and the ability of the macroscopic protuberance to hold a droplet at tilt angles.

a, Photographs of a water droplet (about 5 μl) placed on a FLIPS with ferrofluid 1 (left) and diluted ferrofluid 1 (right). b, Photographs of a water droplet (about 5 μl) placed on a FLIPS with ferrofluid 1 (left) and diluted ferrofluid 1 (right) immersed in dodecane. c, Photographs of a water droplet (about 5 μl) held by a magnet at about 90° and 30° on a FLIPS with ferrofluid 1 (left) and diluted ferrofluid 1 (right), respectively. d, Photographs of a water droplet (about 5 μl) immersed in dodecane and held by a magnet at about 90° and 30° on a FLIPS with ferrofluid 1 (left) and diluted ferrofluid 1 (right), respectively. The comparison between c and d suggests that holding a droplet on the macroscopic protuberance does not require the existence of the wrapping layer and that capillary force is likely to dominate the interaction.

Extended Data Fig. 5 Calculations of the van der Waals interaction energy G132 and disjoining pressure.

a, Dielectric response ε as a function of imaginary frequency ξ for the four phases in the droplet-on-FLIPS system. The ferrofluid line lies between air and water, but below both water and dodecane. b, Interaction energy as a function of the thickness of the ferrofluid wrapping layer for the water–ferrofluid–dodecane configuration. The energy decreases as the thickness decreases, indicating that the wrapping layer is unstable. c, Interaction energy as a function of the thickness of the ferrofluid wrapping layer for the water–ferrofluid–air configuration. The energy decreases as the wrapping layer thickness increases, indicating that the wrapping layer is stable. d, Disjoining pressure as a function of the thickness of the ferrofluid wrapping layer in the water–ferrofluid–air system. The pressures are positive, indicating the formation of a stable thin film or a stable wrapping layer.

Extended Data Fig. 6 Additional adhesion and friction data.

a–c, Adhesion measured on FLIPS prepared with isotropic porous Teflon membrane substrates. lmin is the minimum distance between the test surface and the FLIPS, as shown in the schematics in Fig. 4a. a, Adhesion of FLIPS on a low-energy surface (PTFE), a high-energy surface (glass) and two composite surfaces: a fluorocarbon-oil-based SLIPS (SLIPS1) and a silicone-oil-based SLIPS (SLIPS2). The control is measured between two glass surfaces coated with ferrofluid only and without the porous membrane. b, Dependence of adhesion on ferrofluid viscosity. Ferrofluid 1 (μ = 0.367 Pa s) is more viscous than ferrofluid 2 (μ = 0.040 Pa s). c, Dependence of adhesion on retraction speed. The adhesion decreases with decreasing retraction speed. The test surface is a PTFE surface. Panels b and c suggest that viscous adhesion is the dominant adhesion mechanism. d–i, Adhesion and friction measurements on FLIPS with anisotropic substrates. Pattern 1 is used. The numbering of regions (R1, micro-topography; R2, flat region with a ferrofluid overlayer; R3, macro-topography) is the same as in Fig. 1. d, Adhesion without a magnet and on different regions with a magnet at three different retraction speeds. e, Sample adhesion force curves measured at 1 mm s−1. f, Sample friction force curves measured at 1 mm s−1 and with 100-mN load. The value of the friction force is extracted from the lowest point along the curve. Note a signature of friction in the micro-topographical area of FLIPS, which is much higher than that on either flat or macro-topographical areas, characteristic of typical ferrofluid-coated non-structured surfaces. g, Friction forces without magnets and on different regions with a magnet in the direction parallel to the microchannels. Friction is highest in region 1, in the presence of micro-topography, and lowest in region 3, in the presence of macro-topography. The friction in region 2, with a flat fluid overlayer, is the same as for the entire FLIPS surface with no magnetic force. The difference can be as high as two orders of magnitude between regions 1 and 3, and one order of magnitude between regions 1 and 2 (or between region 1 and with no magnetic force). h, The corresponding friction forces in the orthogonal direction. i, Direct comparison of friction forces in the parallel and orthogonal directions. The error bars in all panels correspond to the standard deviations, calculated from a minimum of five measurements. For details, see Methods section ‘Adhesion and friction experiments’.

Supplementary information

Video 1 FLIPS dual level topographical response.

This video first shows the top view of FLIPS’ topographical responses, particularly the expansion of the micro-topographical area over time. The second and the third parts of the video show FLIPS’ topographical response to a hexagon of six magnets and arrays of magnets with hexagonal symmetries, respectively, and compares the patterns to those formed on an unstructured substrate.

Video 2 Transport of colloidal particles.

This video shows the controlled transport of non-magnetic colloidal particles on FLIPS. A magnetic field gradient is applied and removed repeatedly in the direction of the colloids’ movement through the usage of a small permanent magnet.

Video 3 Switching droplet mobility by removing micro-topography.

This video shows that a droplet is first pinned on the micro-topographical area. Once the magnet is lowered to switch the balance between magnetic pressure and capillary pressure, ferrofluid flows back to the micro-topographical area, allowing the droplet to slide again. The second part of the video is taken under angled illumination.

Video 4 Assembling droplets by fine-tuning the macro-topographical response.

This video shows that droplets are assembled via the macroscopic protuberance and released in distinct clusters of two to five droplets, whose size and geometry are controlled by the distance of the magnet from the surface.

Video 5 Wrapping and unwrapping of a ferrofluid layer around a water droplet.

This video first shows the spontaneous formation of a layer of ferrofluid around a water droplet and its thinning under a magnetic field. When dodecane is added to replace air, the wrapping layer is removed.

Video 6 Mixing with and without the ferrofluid wrapping layer.

This video first demonstrates that the presence of the wrapping layer delays mixing. Two droplets of polystyrene colloids are brought together, but mixing occurs only after the wrapping layer is disrupted by the pulses of the electromagnet. The second half of the video shows instantaneous mixing of a droplet containing sodium bicarbonate with a droplet containing hydrogen chloride and an immediate release of carbon dioxide when wrapping layers are absent.

Video 7 Switchable adhesion.

In this video, FLIPS creates strong adhesion between a top handle and a bottom frame in which a beaker of water sits without magnets. After magnets are installed, the adhesion is reduced, and it is possible to separate the top handle from the bottom frame. Removing magnets switches FLIPS back to its adhesive state.

Video 8 Switchable friction.

In this video, the top central cylindrical disk has FLIPS attached to its bottom, and its rotation is due to the friction between the FLIPS and a stage connected to a step motor. After magnets are installed, the friction is reduced, and the rotation stops. Removing magnets allows the rotation to resume. The experimental results are followed by an explanatory animation.

Video 9 Pumping.

This video demonstrates the pumping capability of a FLIPS pipe. It shows an ethanol solution of rhodamine B being pumped from the right glass vial to the left glass vial, followed by an explanatory animation.

Video 10 Biofilm removal.

This video shows that the topographical responses of FLIPS disrupt and detach an algae biofilm from the FLIPS substrate.

Source Data

Rights and permissions

About this article

Cite this article

Wang, W., Timonen, J.V.I., Carlson, A. et al. Multifunctional ferrofluid-infused surfaces with reconfigurable multiscale topography. Nature 559, 77–82 (2018). https://doi.org/10.1038/s41586-018-0250-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-018-0250-8