Abstract

The increasing need for indium in photovoltaic technologies is set to exceed available supply. Current estimates suggest only 25% of global solar cell demand for indium can be met, posing a significant challenge for the energy transition. Using the WORLD7 model, this study evaluated the sustainability of indium production and overall market supply. The model considers both mass balance and the dynamic interplay of supply–demand in determining indium prices. It is estimated that a total of 312,000 tons of indium can be extracted. However, the primary hindrance to supply is the availability of extraction opportunities and the necessary infrastructure. Unless we improve production capacity, indium may face shortages, hindering the advancement of pivotal technologies. A concern observed is the insufficient rate of indium recycling. Boosting this could greatly alleviate supply pressures. Projections indicate that indium production will reach its peak between 2025 and 2030, while the peak for photovoltaic solar panels due to indium shortages is anticipated around 2090, with an installed capacity of 1200 GW. Thus, the growth of photovoltaic capacity may lag behind actual demand. For a sustainable future, understanding the role of essential metals like indium is crucial. The European Environment Agency (EEA) introduced four “imaginaries” depicting visions of a sustainable Europe by 2050 (SE2050), each representing a unique future set within specific parameters. Currently, Europe is heavily dependent on imports for tech metals and has limited recycling capabilities, putting it at a disadvantage in a global context. To achieve sustainability, there is a need for improved infrastructure for extraction, recycling, and conservation of metals such as indium. These resources are crucial for realizing Europe’s 2050 sustainability objectives. Furthermore, understanding the role of these metals in wider overarching strategies is vital for envisioning a sustainable European Union by 2050, as depicted in the Imaginaries.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In the next decades, fossil hydrocarbons will gradually be phased out from the global electricity production. That implies a large amount of solar photovoltaic and collection of wind energy, as well as much more efficient technologies helping to reduce energy use (Föst & Goldmann, 2021). Indium is an important metal for these new technologies designed for the transition to a low carbon society, and there is much attention turned toward asking if indium can be supplied in the amounts being planned for, and the challenges that arise if indium should have limitations to supply (Bardi, 2013; Sverdrup & Ragnarsdottir, 2014).

New electronics and semiconductors depend on a larger scale on different types of technology metals, such as indium. Indium is an important component in thin-film photovoltaic technologies and LED displays and computer screens (Schuyler–Andersson, 2022; Kopidakis, 2023). For displays, indium tin oxide layers (ITO) are important. Earlier, this has been the main use of indium (Bleiwas, 2010; Panayotova & Panayatov, 2013), but this is changing toward photovoltaics. It is important for making semiconductors and microprocessors used for computers. Indium, in the form of SnO2–In2O3, is also used as an anode stabilizer (Panayotova & Panayatov, 2013). The demand from indium is expected to grow in the future. The supply security of indium, depend on source ores for copper, zinc and lead mining, and there are no indium mines at present. Indium is used in applications where there are limited choices of substitutes (Öhrlund, 2011; Zuser & Rechberger, 2011). Failure to secure indium supply may cause failure of provision of some technologies or reduced efficiencies (Föst & Goldmann, 2021). It is used as a grain stabilizer agent in alloys. For use in alloys, substitutes for indium can be found, for the use in semiconductors, LED and LCD screens and in photovoltaic panels, this is more difficult without losing some functionality (Bleiwas, 2010).

To ensure a long-term sustainable supply of metals for society’s critical functions, it is essential to contextualize the envisioned role of these metals. The European Environment Agency (EEA) developed the following four imaginaries depicting a sustainable Europe by 2050 (SE2050), each presenting a distinct vision of the future and framed in specific conditions (EEA, 2022):

-

1.

Ecotopia Society prioritizes nature and sustainability, reducing consumption and technological reliance. As the public sector contracts, civil society and communities collaboratively drive decision-making and welfare.

-

2.

The Great Decoupling Technological advances and social innovations have uncoupled GDP growth from environmental harm, with the bioeconomy central to this shift. While businesses propel green growth in competitive markets, government interventions guide market incentives, and EU cooperation remains focused and pragmatic.

-

3.

Unity in Adversity In response to environmental, climate, and geopolitical challenges, Europe has unified under a common EU constitution, emphasizing strict economic measures that prioritize the environment. Investments in nature are strongly endorsed to address environmental and climate-related issues.

-

4.

Technocracy for the Common Good State control emphasizes collective societal interests, utilizing digitalization for extensive monitoring of social and ecological systems. The EU is a cohesive alliance of strong leading governments, with centralized economic activity and tendencies toward deglobalization and protectionism.

Each imaginary includes metals and minerals but varies in its approach to production, usage, and circularity concepts. By understanding the circularity of critical minerals, policymakers can make informed decisions on the best instruments to achieve the desired sustainable future, while also considering alternative pathways to reach that particular desired future (Haraldsson & Bonin, 2021; EEA, 2022). Circularity of critical minerals is thus the prerequisite of any imaginaries futures and understanding the evolution of these over time will enable us to align policy processes and important feedback loops related to circularity. No serious assessment of circularity is possible without an integrated systems assessment model, considering the important feedbacks in the system. The imaginaries now presented, are part of the first steps of a process that will be iterated into new, improved imaginaries in the future.

Figure 1 shows how the extraction of metal and materials are linked in a complicated system. Technology metals, indium is one of them, are all of them dependent on primary extraction of a major resource such as hydrocarbons, metals or phosphate that produce a refining residual where the technology metals are contained. All metals or minerals indicated with color have their own primary mines, such as copper. All the metals without color have no mines of their own, all or most extraction is dominated by secondary extraction from refining waste from one of more primary metals. The elements on top are present in deposits in amount of billion tons, those in color below are present in million tons. This complicated system is contained inside the WORLD7 model. More elements than this are included in the WORLD7 model (50 metals and mineral in 2023).

Map of interdependency of extraction of different metals. Many technology metals (Cd, Ga, Se, Ge, Te, In) are dependent on primary extraction of a major resource such as hydrocarbons, metals or phosphate. All metals or minerals indicated with color have their own primary mines, all those without color, all extraction is dominated by secondary extraction in some way

Objectives and Scope

Our goal was to develop an integrated dynamic model for the global market for indium, and include it in the WORLD7 Integrated System Dynamics Assessment Model. The zinc, lead, copper and silver production rates from WORLD7 were used for driving the indium extraction module. We explored the indium supply system and explored if the future supply is sustainable and explored if future demands for indium for photovoltaic panels can be satisfied. We included the whole global system in a generalized way; simulations cover the past and future (1930–2023–2200). We wanted to ensure that it can reconstruct the past with respect to extraction, recycling, supply and market price. The WORLD7 model has been used for a number of sustainability assessments for individual metals. Indium is a key metal for several important technologies that are important for a transition to renewable energy sources. This was to assess how sustainable indium use is for renewable energy. Environmental problems and sustainability issues are so interlinked and complex systems that no serious policy planning can be done without assessment models.

Background

Use of Indium

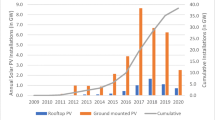

Flat-panel displays and touch screens account for 65% of the demand in 2022. Copper–indium–gallium–selenium (CIGS) photovoltaic panels have 22–25% efficiency and are expected to drive future demand for indium, gallium and selenium significantly. Many of the different solar panel technologies use indium in small amounts (Tables 1 and 2). The solar conversion efficiency is expected to reach 35% in the near future (Kopidakis, 2023) for the technologies using indium. This will simultaneously drive the demand for indium, gallium, and selenium (Föst & Goldmann, 2021; North of 60 Mining News, 2023). This type of panels have 12% of the market in 2023, and are expected to increase significantly. A short summary of our work on the technology metals (Ag, Bi, Cd, Ga, Ge, In, Se, Sb, Te) was published at the World Resources Forum in 2016 (Sverdrup et al., 2017a, 2017b). This is the full story for our work on indium.

Earlier Work on Indium Resources and Supply

Figure 2 shows the global indium production and indium market price according to the USGS ds140 program, (USGS ds140, 2019; United States Geological Survey (USGS) Mineral Commodities Summaries, authored by Tolcin (2013, 2015, 2022) and Schuyler–Andersson (2022). More recent data were added by the authors from various literature sources. The production and price data were used for validating the model performance. The extraction in 2022 was about 950 tons, China was the largest producer with 530 tons/year, followed by South Korea with 200 tons/year, Japan at 66 tons/year and Canada at 55 tons/year. Small producers are Belgium, France, Peru and Russia. Some refineries have the infrastructure to produce significant amounts of indium if they were to decide to do so. These are the large zinc, lead and copper refiners and producers using sulfide ores, or those with large sulfide ore refining capacity (Sweden, Poland, United States, Chile, Germany). In addition, China has a focus on extracting the strategical metals at their large metal refineries.

Indium production and market price according to the USGS DS140 program, (USGS, 2019, 2022; Tolcin, 2013, 2015, 2023; Schuyler–Andersson, 2022). More recent data were added by the authors from various literature sources. The indium price was adjusted to 2022 United States dollars. Since 1970, the indium metal price has been volatile

Meadows et al. (1972, 1974) pointed out global sufficiency of natural resources in their pioneering study “Limits to growth”. More recent studies by Bardi (2013), Sverdrup and Ragnarsdottir (2014) and Graedel et al. (2015) elaborated on the subject. These studies presented different types of metal supply assessments and estimated scarcity and future peaks in production for many natural resources. Not all studies we have seen appreciate the implications of indium being a secondary dependent metal. Earlier works have in common that they have focused on smaller parts of the indium system, like demand, but not really the whole system: Halada et al. (2008), Gibson and Hayes (2011), Graedel et al. (2015), Viehbahn et al. (2015), North of 60 Mining News (2023). Bleiwas (2010) explained the basics of this for cadmium, gallium, germanium, indium, tellurium and selenium.

Demand for photovoltaics was worked on by several authors; Bleiwas (2005), Fthenakis et al. (2009), Moss et al. (2011), Zuser and Rechberger (2011), Candelise et al., (2012), Fthenakis (2012), Goe and Gaustad (2014), Stamp et al. (2014), Elshkaki and Graedel et al. (2015), Grandell and Höök (2015), Kim et al. (2015), Davidson and Höök (2017), Almosni et al. (2018), and Månberger and Stenqvist (2018). Öhlund (2011) listed eight metals on which the transition to a low carbon society will rely, indium is one of these. There is no real consensus among these on future indium demand, and the demand estimates vary a lot. The demand estimates were based on three approaches: (1) a fixed percent increase per year for the next 20 years, (2) scaled with global population, GDP, and an assumed technology shift curve, or (3) estimated from engineering estimates of solar energy and technology needs, and recalculated to indium material need. We made our demand estimates guided by these earlier studies, but indium for photovoltaic technologies were derived from the energy module inside WORLD7.

Refining and recycling aspects were treated by several authors: Demarthe et al. (1990), Alfatanzi and Moskalyk (2003), Alonso et al. (2007), Johnson et al. (2007), Parks et al. (2009), Salhofer et al. (2011), Zeng (2011), Ruan et al. (2012), Zimmermann (2013), Reuter et al. (2013), Zimmermann and Gössling-Reisemann (2014), Nassar et al. (2015), Redlinger et al. (2015), Gutowski et al. (2016), Li et al. (2020), and Lin et al. (2021). Panayotova and Panayatov (2013) gave examples of recycling rate for different processes, as well as indications of losses in different production stages of indium use. Many processes have low indium utilization, and low recovering rates. Once material has been recovered and is chemically treated, recovery of indium from scrap can be from less than 50% to nearly 90% effective in the best cases. Indium is recovered together with germanium (Ge), arsenic (As) and cadmium (Cd) from zinc refining residuals such as roasting dust, anode slimes, slags (Panayotova & Panayatov, 2013). Yields for the indium recovery from zinc, copper and lead refining residuals are shown in Table 3. Research is ongoing to improve extraction and recycling processes for indium (Zürner & Frisch, 2019; Drzaga et al., 2021; Lin et al., 2021). Dahmus and Gutowski (2007) discussed the mechanisms of the economic feedback on recycling. Today, the recycling rate for indium is low in all sectors where indium is used. From a sustainability and materials conservation point of view, the recycling from the total indium flow in society is passively driven by price and low (10–15%). Different aspects on mining rates and available resources were studied or reported by Weeks (1973), United States Department of Interior (1980), Wellmer et al. (1990), Briskey (2005), O’Regan and Moles (2006), Zhucheng et al. (2007), Singer (2007, 2013), Phipps et al. (2008), Wang et al. (2011), Prior et al. (2012, 2013), Tolcin (2013), van der Voet et al. (2013), Woodhouse et al. (2013), Kelly et al. (2014), Ting et al. (2015), Brown et al. (2015), Mudd et al. (2014), Paradis (2015), Nassar et al. (2015), Werner et al. (2015), Lokanc et al. (2015), Tolcin (2015), Frenzel et al. (2016, 2017), Mudd et al. (2017), Werner et al. (2017a, b), Li et al. (2020), Zhou et al. (2021), Schuyler–Andersson (2022) and Tolcin (2022). There is not great convergence between the studies on resource size.

Schubert et al. (2008) attempted to model indium supply and recovery using a simple econometric model of the Hoteling type. These types of models are heavily dependent on calibration to a dataset and generally have poor prediction capability. They are not really able to predict price without making assumptions that force the model output. We noticed one earlier study using a system dynamics approach to the situation for indium (Choi et al., 2016). It is a simple model focusing on zinc and indium, with limited market dynamics, the feedbacks are few. The zinc supply in their model was based on historical statistics for the past and guessing the future zinc production, and thus predefined. The standard drivers are to a large degree based on World Bank future extrapolations, assuming continued growth without any future restrictions. It uses the mass flow push-through approach. Stamp et al. (2014) used a simple model for estimating indium demand based on future energy scenarios; however, the model did not have any source of indium, it was only a partial model. For a sustainability assessment, the approach is incomplete and insufficient. Elshkaki and Graedel (2013, 2015) used a flow-through model for a simple materials limitations assessment for new electricity technologies. Flow-through models are simple to make in a spreadsheet, but they lack all market dynamics. Busch et al. (2014) made a flow-through model with stocks and flows, run in hierarchical order in a spreadsheet system. Yoshimura et al. (2013) made mass flow charts for the global scale for indium. No market dynamics or any systems feedbacks were considered in any of these studies. Lin et al. (2021) used a flow-through model for assessing the indium situation for Chinese industry. The model was based on a linear flow chart, with recycling from waste and indium tin oxide production. They reported on the amounts mined (21,000 tons) and imported (3600 tons) by China and assessed future demands and possibilities for supply. About 60% of all products with indium were exported. During the same time, China recycled 630 tons indium. Subtracting the exported amount, China recycled 11% of its internal indium. Stocks-in-use are reported to be about 3200 tons of indium. Licht et al. (2015) made a global flow-through model for gallium, germanium and indium supply.

Marwede and Reller (2014) made a life cycle analysis for indium in photovoltaics. Life cycle analysis compares components separated widely in time and miss many aspects of the dynamics in the system. All these studies were of limited scope and fell short of the objectives of this study. The many primary extracted metals were done earlier with the WORLD7 model, a selection of studies that demonstrated how the model operated would be: silver (Sverdrup et al., 2014), aluminum (Sverdrup et al., 2017b), platinum group metals (Sverdrup & Ragnarsdottir, 2016b), copper, zinc, lead (Sverdrup et al., 2017b, 2019a, 2019b), molybdenum and rhenium (Sverdrup et al., 2018). Cobalt is a metal extracted both in primary mines and as a secondary metal (Sverdrup & Ragnarsdottir, 2016a). The WORLD7 model handles in total 50 different metals, 8 minerals and 12 man-made materials (Sverdrup 2020). More recently, Michoux (2019; 2021a; 2021b; 2021c) estimated metal requirements for some types of technology metals demanded for the next 50 and 100 years, showing that demand far exceed the available resource supply, even under optimistic assumptions of extraction conditions. His analysis did not include indium, but the pattern across the board was characteristic of the general large mismatch between demands and real supply ability.

Methods and Theory Used

Modeling

For the modeling, we used the established methods of systems analysis (Senge, 1990; Sverdrup et al., 2022). We analyzed the system using stock-and-flow charts and causal loop diagrams. The system dynamics software used was STELLA®Architect supplied by ISEE Systems (ISEE-Systems, version 3.5, 2023). The Integrated Assessment Model WORLD7 was used for this study (Sverdrup et al., 2019a; Sverdrup & Olafsdottir, 2019a; Haraldsson and Sverdrup 2021; Olafsdottir et al., 2019; Olafsdottir and Sverdrup 2021; Sverdrup et al., 2021) and can be obtained from the authors. The workflow was as follows:

-

1.

Model development

-

a.

Develop a simulation module for indium for inclusion in the WORLD7 model.

-

b.

Use the WORLD7 integrated modeling framework to generate the technology element demand from the production of consumer goods and technological infrastructures.

-

a.

-

2.

Parameterize

-

a.

Identify databases on production, market price and extractable resources and reserves and where these are located.

-

b.

Estimate the available extractable indium that can be extracted from deposits, considering extraction technologies, yields and the cut-off caused by resource qualities and costs of extraction as related to the market price dynamics.

-

c.

Set other model parameters based on observation when available.

-

a.

-

3.

Model use

-

a.

Run the WORLD7 model to assess the supply sustainability from the first use of the technology metals to about 2200. Run Business-as-usual and a demand sensitivity assessment.

-

b.

Evaluate the model simulations with respect to result validity, and risk for future aspects of scarcity.

-

a.

-

4.

Conclude

-

a.

Develop policy implications.

-

a.

The reserves and resources estimates for the source metals were based on geological estimates, interpretation of geological data, and allocation of extractable amounts according to ore quality, stratified with extraction costs (Sverdrup & Olafsdottir, 2019; Sverdrup & Ragnarsdottir, 2014; Sverdrup et al., 2018).

Resource Estimations

Resource estimation for indium always come with a lot of reservations. This is so because there are no indium mines and indium extraction is conditioned on the extraction of its source metals. Indium is derived from additional extraction from refining anode residuals from zinc, lead, copper and silver. Recycled mother metals have little content of indium. Indium is only available if the ore is hydrometallurgically processed and little indium comes out with heap leaching methods. Opening up indium mines is being considered, but the deposits being considered so far are small.

Only a few studies made detailed studies of the available resources of the technology metals. Brown et al. (2015), Frenzel et al. (2015, 2016, 2017), Werner et al. (2015; 2017a; 2017b), Tolcin (2013, 2015, 2022), Ting et al. (2015), Schuyler-Anderson (2022) and USGS (2022) ds140 program reported on production rates and estimates of reserves or resources (Briskey, 2005). Brown et al. (2015) reported on indium in different deposits for the USGS MCS program. One major source of difference among the available resource estimates in the literature are the differences (or lack) of assessment of actual industrial extractability (United States Department of the Interior, 1980; Wellmer et al., 1990; Singer, 2007, 2013). That a deposit has a certain amount of metal does not mean that it can all be extracted.

Extraction cut-off is dependent on technology and degree of repetitiveness of the extraction method. It is composed of different elements: The access yield is the part of the deposits that will be available for this kind of extraction. Some deposits lack physical or legal access, have a composition that prevents extraction or the extraction operation does not have the infrastructure to extract the technology metal when the operation is running (YA). The mining yield (YM) is the amount of known and mapped reserve that will be extracted, counting in dead zones, blocks left for other purposes, rock between tunnels and similar causes. The substrate yield (YS) is the fraction of the potential in the source metals that will actually be extracted as a secondary substrate, also dependent on whether adequate extraction technology is present or not. Some methods, such as heap leach do not readily give such a secondary substrate. The refining yield is the fraction of the metal recovered from the refining substrate (YR). The extraction cut-off is dependent on technology, extraction costs and metal price at the time. The recoverable amount is estimated using (Krautkrämer, 1988; Johnson et al., 2007; Raabe, 2023):

The substrate yield is:

The extraction cut-off is determined by the technology used for extraction, combined with several cost aspects of extraction. As example, if the extraction substrate has 150 ppm indium, and the cut-off used is 30 ppm, then the substrate yield is 0.8. Y is the overall yield, the amount metal extracted divided by the total metal content in the original ore (Eq. 1). Indium is at present extracted mainly from zinc and lead ore refining residuals. In the model, indium is extracted from zinc, lead, copper and silver, the total rate (r) is the rate from each contributing metal:

where the contribution from each source metal refining residual follow this type of equation:

where rZn is the zinc primary extraction rate, xZn is the fraction of indium in the zinc flow, YZn is the total extraction yield for indium from zinc and f(Zn) is a zinc mining technology enhancement function (Sverdrup et al., 2017b, 2019b). Indium extraction before 1950 was very small. In the model, the content is specified as a weight fraction in the source material and then calculated from the primary flows in the simulation. In these estimates, it is necessary to account for limited access, the kind of extraction method, if infrastructure is available, if the ore allows for it to be extracted and the extraction yield.

Table 3 shows the recoverable resources of source metals in million tons of metal, this was used as input data to the WORLD7 model (Sverdrup & Ragnarsdottir, 2014; Sverdrup et al., 2017a, 2017b; Sverdrup & Olafsdottir, 2019). Experiences learned from studying corporate reports and scientific literature discussed in the text were reworked into the resource data and the estimates of costs of extraction. The data were stratified with respect to ore metal content and relative extraction cost (Phillips & Edwards, 1976). The amount of mother metal (URR) in total when the simulation started in the model (1850) was stratified with respect to ore quality and indium content (ppm or g/ton rock). The ore classifications were described in detail in Ragnarsdottir and Sverdrup (2014). The sum was the amount of indium potentially available in the mother metals. Then came our estimates of the different types of yields, and what we thought can ultimately be recovered of the potential amount (URR).

Indium is mostly found in ores of sphalerite (ZnS). Some indium is found in some tin and silver ores, but very little of this is recovered today. The content in the ore varies from 1 to 100 ppm, depending on the deposit. Some silver deposits have as much as 3900 ppm of indium (Panayotova & Panayatov, 2013). On average, high grade zinc ore contains about 150 ppm of indium, or corresponding to 0.015% by weight (Werner et al., 2015). Extraction cut-off is normally set at 100 ppm (0.01% weight) for extraction from zinc (Frenzel et al., 2015, 2017). With only 50–60 ppm of indium ending up as being recovered, this is 161,000 tons of indium. In primary copper, the indium content is on average 5 ppm, but some copper ores have as much as 80 ppm. In primary lead, the indium content is on average 4 ppm, but some lead ores have as much as 30 ppm (Lokanc et al., 2015). Frenzel et al. (2016) indicated indium content in different types of zinc deposits. The indium content given is for sphalerite in ore and must be recalculated to what is really obtained when the ore is mined. Certain tin deposits in Cornwall have as much as 50–100 ppm indium in the ore. Potentially, aluminum deposits with gallium may as well have traces of indium due to the similarity of the two; however, this has so far not yet been significantly exploited as a source.

Indium extraction may be developed at larger refineries associated with primary silver mines. The extraction yield from zinc–lead ores are in the range of 70–90%. About 35% of the indium present in zinc reach a refinery that will be capable of extracting it (Raabe, 2023). That means, that of 548,000 tons indium present, about 150,000 tons indium could be extracted as the world looks now. Jorgenson and George (2004) reported that the average indium content in zinc ore was 0.028 kg/ton zinc ore. Lin et al. (2021) reported that the indium contents in Chinese ore are on average 50 pp in zinc ores, 50 ppm in lead ores, 40 ppm in tin ores, and 10 ppm in copper ores. During extraction, about 20% of the indium content in the ore end up in the zinc metal extracted. Lin et al. (2021) reported that lifetimes for LCD devices are on average 8.5 years in China, 4.5 years for computer devices and 2.5 years for smartphones. Table 4 is a continuation of Table 1. From the average content and the mother metal rate, we may estimate the approximate indium production potential. Whereas it would be possible to make about 1,480 tons/year, only 950 tons/year is extracted at the moment. The potential implies that another 530 tons/year may be produced, an increase of about 56%. This is somewhat more than earlier reported (Idoine et al., 2022).

Table 5 shows the refinery supply of indium to the market according to the USGS Minerals Yearbook for 2022. The amounts are in tons/year. The technical extraction capacity is maybe at 1100 tons/year at present, 200 tons more than the present production. Japan and South Korea appears to have a capacity available. Presently, the market is dominated by China and South Korea. There is some difference between the estimates of the USGS Minerals Yearbook 2021 (Tolcin, 2013, 2015, 2022; Anderson, 2022) and the British Geological Survey (Idoine et al., 2022). The difference may be interpreted to illustrate the uncertainty in the available data. This shows that the data do not represent the “truth” but a best available estimate of what appears to be there.

Table 6 shows different estimates of reserves and resources for indium. There are other studies, but these fail to understand the difference between reserves and resources and make naive assumptions on extractability; they have been discarded from this study. We had access to new data with estimates of Cu, Zn and Pb resources (Sverdrup et al., 2017b, 2019b) and this is one reason why our present assessment of mother metal resources is different from earlier assessments. Our estimate coincides with that of Werner et al. (2017b). The yields assumed by the different studies remain undefined. The total estimates of Werner et al. (2017b) and our estimate are within 10% of each other. The earlier estimates were substantially lower. Werner et al. (2015, 2017a,b) did a thorough analysis of deposits for copper, zinc and lead containing indium, listing known reserves and inferred reserves remaining to be found, with their estimates of contents. They started their assessment on existing mines, having data on size and metal contents. This differs a bit from our approach, as we included resources not mined and considered as existing but not yet identified at the moment, arriving at significantly larger Zn resources than the ones reported by Werner et al. (2017b); see Sverdrup et al. (2019a, 2019b) for details of the difference. Werner et al. (2015; 2017a; 2017b) focused on indium content in geological deposits, but did not appear to consider any extraction yields. Our estimates were larger for copper and zinc, consistent with the USGS estimates (Hammarström et al., 2019). A large uncertainty was associated with the contents in undiscovered and unidentified hidden deposits, and a number of assumptions must be made. Despite the differences, we arrived at the same approximate size for the available indium resource. The earlier studies of Moss et al. (2011) and Lokanc et al. (2015) ignored indium in copper and silver deposits and did not consider extraction yield, and Paradis (2015) ignored indium in lead and silver deposits, delivering underestimates for the total available resource.

Tables 1 and 2 show the technology metal uses in electronics and high technology equipment and in photovoltaic solar (Cucchiella et al., 2015; Cesaro et al., 2018). The amounts are given in g/unit of indium in Table 1. The CIGS thin-film cell is composed of a CIGS compound, the chemical formula of which would be CuIn0.6Ga0.4Se2. In Table 1, at least 10 different technologies are listed. Ten of these photovoltaic technologies require indium, five of them require gallium in addition to indium, three of them require antimony in addition to indium, one technology requires tellurium in addition to indium, three of them require selenium in addition to indium and six of them demand silver in addition to indium. The available indium in the markets can be used for many different photovoltaic technologies, all of them important and several are mutually linked and depending on each other in combinations (Tables 1 and 2).

Table 2 shows kg of indium per installed MW capacity. We set the indium used to decrease from 30 kg indium/MW in 2000 to about 10 kg indium/MW by 2070 in the WORLD7 model in solar panels, implying that indium use becomes more efficient with time. This is a simplification applied at the moment. Lin et al. (2021) gave 23.2 kg per MW for CIGS and 21 g/ton LED lighting. The content in LCD screens is 0.4 kg/ton. Cars have each 0.3 gram of indium. The total car fleet has about 1.4 billion cars, they all contain 420 tons of indium (Lin et al., 2021).

The maximum number of technology items that can be produced, can be estimated using an analog with Liebig’s Law for maximum harvests in a cropping system, the maximum production is equal to the rate corresponding to the nutrient in least supply (von Liebig, 1840, 1843; Liebig et al., 1841). Beside the requirement for each individual technology, we need to account for the fact that possibly all of them will exist simultaneously. Then, of the whole amount of indium, a part of the indium must be allocated or distributed among the different technologies. In the WORLD7 model, this was done proportionally with initial demand for each sector, with equal priority for all. Other principles for distribution would be possible. When taking indium from recycled scrap, the yield in extraction is in the range of 75–90% (Lokanc et al., 2015).

Lokanc et al. (2015) reports that the indium reserves were 15,000 tons in 2015. The term “reserves” is misleading for indium, and the amounts are only potentially available, if the mother metal is really mined. And, indium is not something that can be normally mined by any independent decision. For what can be extracted requires assessment of availabilities at sites where mother metals with indium content are mined and if the required technical installations can be made available there. There are no primary mines for indium at present. At present, minor amounts of indium are extracted from copper sulfide ores and more could be taken out (Lin et al., 2021). During zinc refining, indium accumulates in the slag and in the flue gas dust. When zinc is electrolyzed, indium accumulates in the anode sludge. The same occurs in electrolytic refining of silver, copper and lead. Indium production is constrained by the amount of zinc and copper sulfide extracted per year. We estimated the supply potential of indium to 1300 tons per year from zinc ores and 20 tons per year from copper sores. In 2021, indium production was 920 tons per year (Table 4). The mother ore content was adapted from unofficial information found in company websites. We consulted the mineral commodities summaries (USGS MCS program) and the associated statistics (USGS ds140 program, it unfortunately was stopped in 2019) for the years 2011, 2013, 2015, 2018, 2019, 2020, 2022, 2023. Demand was adapted for the model using the study of Stamp et al. (2014).

Model Description

Figures 1, 3 and 4 show simplified flow charts for the indium module in WORLD7. The extraction pathway for a metal in general is shown in Figure 3. The flow chart for a typical secondary metal has many conversion stages where material can get lost. Thus, for all the secondary metals, overall extraction and recycling yields are a challenge. The recycling part of the flow chart still has transaction losses, preventing full circularity. To maintain the stocks-in-use, fresh material input must match the irreversible losses of the system.

Figure 4 shows how the residuals containing indium (anode slimes) flows from zinc, copper, lead and silver refining to indium extraction and from there to the market. Indium flows for the market to four types of use in society. In the model, we ignored the small amount indium found in tin deposits. Indium flows from mother metal deposits to secondary residuals from which indium is extracted. After refining, indium goes to the market for sale and gets incorporated into different uses in society. After ended use, the indium flows to scrap. From scrap, a fraction is recycled and the rest is lost to generic waste where it can no longer be retrieved.

The causal loop diagram for indium production and supply is shown in Figure 5. The diagram describes how the mass balances in the model are related and represents the differential equations used. R represents reinforcing loops. There are a number of loops that are important. R1 is the loop that produces indium and generates a profit. The indium extraction is driven by the commercial profits on extracting indium from the mother metal extraction residuals. Using of profits and adding extraction infrastructure promotes (R2) more indium extraction and more profits. The desire for more profits drives the decision to invest in more capacity. These feedbacks drive the system. Because the indium profit is very small compared to the mother metal profits, there is no significant feedback back to zinc, copper or lead mining from the indium price. An increase in indium demand increase the indium price, but this does not affect zinc, copper and lead mining significantly. Recycling is another loop that supplies indium into society. These are marked R3a, R3b, R3c and R3d. There are four of them, one for each indium use category. Recycling works like mining, it is thus called urban mining. There are four reinforcing loops, each running over the sectors we have considered, and driven by the profits that can be gained from recycling. There are some balancing loop to pay attention to. The causal loop marked B2 means that, if there is less indium in the market than what the price-modified demand asks for, then there will be a physical shortage to supply. B1 means that indium can only be extracted as long as there are anode slimes to take from. A change from acid leaching of primary metal ore followed by electrolysis to heap leaching and electrowinning, reduces the amount of anode slime and the possibility to extract indium. B3 shows that recycling required that the scrap with indium must be collected and physically brought to a place where the scrap can be refined for indium. The loops B4a, B4b and B4c are the cost loops of extraction. Most of the focus on the industry have been so far on these. They are very important at the corporate level, but in the bigger picture, the whole system must be considered. There many more balancing loops, but those mentioned are the most strategically important, where policy must have a focus.

One ton of zinc costs about 3500 US$. The indium content is about 50–100 g (50–100 ppm), costing about 50–100 US$, or about 1.5–3% of the value. The indium price would have to be 10 times higher to start to matter for the mother metal refining and to boost recycling powerfully. A zinc refining sludge would have 10–50 times more indium and is then interesting as an indium ore. In 2023, a CIGS photovoltaic cell used 20 kg indium per MW installed effect (Cucchiella et al., 2015; Cesaro et al., 2018; Raabe, 2023). We assumed this to reduce over time (Figure 6b). After indium has been scrapped, the metal price will have a promotion effect in causing somebody to recover it (Sverdrup et al., 2019b; Raabe, 2023).

(a) Empirical price curve used in the model. The curve shape is the same as curve shapes developed earlier (Sverdrup & Olafsdottir, 2019). The market is the instantly tradable amount. This amount is related to the price using this curve. (b) Tons of indium used per GW installed photovoltaic panel in the model simulation. (c) Development in efficiency of solar panels with time used in the model simulation. Diagrams (b) and (c) are adapted from Kopidakis (2023)

The indium price has an effect on indium demand, but it does not have any significant impact on indium extraction, as this is dependent on the mother metal extraction rate and availability of indium extraction infrastructure. In the model, purchases from the market were driven by demand, driving supply indium into society where it stays until scrapped or removed by wear and losses. Demand was estimated from average affluence, expressed as disposable income per person and global population, using outputs of the WORLD7 model (Sverdrup et al., 2019b; Sverdrup, 2019).

Figure 6a shows the empirical price curve used in the model. The curve shape is the same as the curves developed earlier (Sverdrup & Olafsdottir, 2019). The market is the instantly tradable amount. This amount is related to the price using this curve. Figure 6b shows the amount of indium used as tons per GW installed photovoltaic panel in the model simulation. At present, 20 tons/GW is required; we assumed that that can be reduced to 10 tons/GW by 2060. This is a curve we have assumed to reflect future technological development. If it does not happen, only half as much installed GW based on indium would be realized. Figure 6c shows the development in efficiency of solar panels with time used in the model simulation.

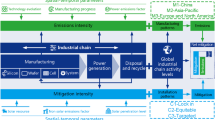

Figure 7 shows an overview of the WORLD7 system. The market dynamics and the price model are explained in Sverdrup and Olafsdottir (2019). Every box in the picture represents a sub-model with one or more dynamic models inside. WORLD7 was built in a modular way, the whole model was like a global arena. The WORLD7 model is a global scale model and it has so far not been divided into regions.

Figure 8 shows the indium module in the STELLA Architect software inside the WORLD7 system. It has four submodules: (1) for indium use in society; (2) for simulating the demand; (3) for the market and indium global trade; and (4) for the extraction of indium from five different sources. Indium is used in society as incorporated into solar panels, in alloys, in semiconductors (computers, mobile phones and screens) and other uses, which is a collection term for everything else. This is a representation in the STELLA software of the causalities mapped in the causal loop diagram shown in Figure 5 and the flow charts shown in Figures 1, 3 and 4 (The principles of how to do this is explained in great detail in Sverdrup et al., 2022). The stocks in Figure 5 can be found in Figure 4. The market module, where demand, modified demand, inputs from extraction and recycling and the available market amount for trading interact to create the price every timestep, follows the logic of Sverdrup and Olafsdottir (2019), and it is the same principle as applied for all globally traded commodities in WORLD7.

Results

Base Metal Mining, Copper, Zinc, Lead and Silver

The source of indium, the primary production of copper, zinc, lead and silver were obtained in the WORLD7 model, and these are plotted in Figure 9. The zinc supply from primary mining peaks in 2024–2032 at a zinc production of about 20 million tons of zinc per year. About 3 million tons/year come from recycling and secondary extraction and this flow has no indium. The copper primary mining is predicted to peak around 22 million tons per year in 2025–2030. The total copper supply is significantly larger because of secondary production and recycling (estimated to be 32–35 million tons per year in 2030), but these copper streams have no or little indium. Lead peaked in 2018 and is in slow decline because of a long term strategy to decrease lead use. This is driven by environmental concerns and worries over toxicity to humans (UN/ECE–LRTAP 1998). Much of the recycled lead is used to offset mining, and it has little indium content. Lead is very toxic to humans, and it has been phased out from many uses. Silver production is expected to peak in 2060 and then decline slowly. Silver recycling is fairly good, and it is predicted to further increase. Figure 9 shows the primary extraction rate of zinc (Figure 9a), copper (Figure 9b), lead (Figure 9c) and silver (Figure 9d).

Primary extraction rate of the mother metals, zinc, copper, lead and silver in the WORLD7 model (Sverdrup et al., 2019b). The rates do not include recycling nor secondary sources, as indium is extracted from refining residuals from primary extraction. Lead extraction has already peaked, as a result of environmental regulations and from prohibiting lead in automobile fuels

Indium System Dynamics Simulations for Business-as-Usual

Indium extraction depends mostly on secondary extraction from copper and zinc and from polymetallic ores. The demand for indium in 2016 came from use in solar energy (150 tons per year), LED lighting (800 tons per year) and for flat-screens, computers, monitors, mobile phones, tablets (1300 tons per year). All of these demands have increased to 2023, still LCD was the dominant use as indium–tin oxide, but that may change in the near future. Smaller amounts are used in specialty alloys.

Figure 10a shows the simulated demand for indium, the demand after price modification, the supply to society, the extraction and the amounts recycled. The production of indium is limited to some extent by the fact that only a fraction of the metal refineries is technically equipped for efficient recovery of indium. Significant investments would be needed in order to increase production. This is consistent with our estimates.

(a) Demand, modified demand after price feedbacks, supply and total extraction for indium. (b) Recycling over time for indium. (c) Supply in kg per person and year and the stock-in-use in kg per person. (d) Simulated price for indium and the market amount of tradable metal. (e) Supply into different sectors. (f) Stocks-in-use, these provide utility

Figure 10b shows the recycling rate for indium, this depends on two factors, a driver from price and improving recycling yields with time, as well as the amount waste to recycle from. The recycling rates are at present very low, partly because of technical challenges. It is built into the model that the recycling methods will improve as a result of research into the topic. If this anticipated development were not to happen, then indium shortage would come earlier.

Figure 10c shows supply per person and year reflects the amount available to compensate for continuous losses and any surplus available for growth in the stock-in-use. Stock-in-use per person is an indicator of the utility gained from the resource, and a decline in stock-in-use suggests a decline in service provision from that resource. Indium production depend on copper and zinc mining, some silver ores contain significant amounts of indium. In production supply will reach peak capacity around 2040–2050, whereas mining has a maximum about 2035. Some business analysts (e.g.,, Gibson & Heyes, 2011) suggested a future large increase in demand that were used as input to the sensitivity analysis. If the increase in demand is larger than the underlying growth in zinc production, the prices can be expected to rise sharply, and that there may be problems with extraction to keep up with demand. An increase in zinc production is not necessarily matched by an increase in indium production, unless the necessary investments are done to make it possible.

A present, the rate of indium recycling is small, and this needs to improve for indium supply and use to become sustainable. Indium prices have in the latest years fluctuated in distinct cycles between 200 and 1000 $/kg. The simulated price is shown in Figure 10d. In Figure 10a, it can be seen how indium demand and the price-modified demand separate about 2025–2028; this is called soft scarcity. This is repeated per use sector in Figure 11a. The indium supply separates from indium demand after demand price modification, suggesting physical indium shortage. This implies that the reduced indium demand cannot be supplied, regardless of willingness to pay. This is the point in time when the indium price shoots up. The indium shortage is caused by the indium demand increasing faster than the increase in indium extraction capability, in combination with the extraction rate depending on the source metal extraction rate, which is insensitive to indium demands. The physical indium shortage and the dependence on an unresponsive source metal extraction rate may have ramifications for the production of large volumes of solar panels for electricity generation. This can be mitigated by a more systematic approach to having the necessary indium extraction infrastructure and by managing indium recycling to be promoted both by market mechanisms but also by improved regulations. For China, Lin et al. (2021) reported indium stocks-in-use of 3200 tons in 2020. Traditionally, semiconductors have so far been the main use of indium.

(a) Source of indium from different mother metals. (b) Cumulative amounts extracted during 1950–2200. (c) Demand and modified demand for the different sections. (d) Cumulative demand. (e) Demand, the price modified demand, the supply and the scrapping rate of the indium in use for solar panels. (f) Total indium supply as part of total demand (soft plus hard scarcity) and supply as fraction of modified demand (hard scarcity)

In 2030, photovoltaic sector will overtake the semiconductor sector in consumption of indium (Figure 11e). Figure 11b shows the source of indium from silver, copper, zinc and lead extraction. Figure 11c shows the cumulative indium demand and modified demand for the different sections. The difference between supply and extraction must come from recycling. Take note that the demand far exceeds the price-modified demand, the difference is the soft scarcity. The price-modified demand in turn exceeds the supply during 2024–2028, this is hard scarcity for indium. Figure 11c shows the cumulative amounts indium extracted 1950–2200. Figure 11d shows the cumulative extraction from different mother metal sources (Silver, copper, zinc and lead). Figure 11e shows the indium demand, the price-modified demand, the supply and the scrapping rate of the indium in use for solar panels. In 2036, demand and supply separates. Peak in utility occurs in 2100. The diagram shows that the demand for indium far exceeds the available supply. Figure 11e shows the demand, modified demand and actual supply of indium for solar panel technologies. The fourth line shows the rate of solar panel scrapping. Figure 11f shows the total indium supply as part of total demand (soft plus hard scarcity) and the supply as fraction of modified demand (hard scarcity).

Testing the Model

The indium module inside the WORLD7 model has been tested against the recorded mining data derived from the USGS (2022) ds140 databases and some additional information from the internet. All the data are not totally consistent, but indicate a band where the real numbers are most likely. That implies that there is no absolute truth in the data found in the literature and on internet sources. The model does reproduce the observed mining rate satisfactory when the model is driven by market demand and price dynamics. The results showed from good correlation with the observed mining data as can be seen from Figure 12c. The metal market price pattern is reasonably well simulated for indium (Figure 12a, b). Figure 12d shows the cumulative amount indium extracted according to data and as simulated. Note that there was no systematic bias in the calculation of the cumulative amounts. We concluded that we could reproduce extracted amount and price consistent with the observed patterns.

Testing the performance of the model on data: (a) and (b) shows the model performance on the available data; (c) shows the simulated supply and production of indium as compared to the data (USGS 2019 and additional data found by the authors from the cited literature and internet sources); (d) shows cumulative amount extracted according to data and as simulated

Discussions

Reserves and Extractable Amounts of Metal

Indium may be present in future discoveries of zinc, copper, silver and tin deposits. The content of indium in the source metals are very approximate. Although most of the global production is as a by-product from zinc mining in China, South Korea, Japan and Canada, very little information is available on actual sources on a global level,. To some extent the information is available at the corporate level, but a broad in-depth compilation is still waiting to be done. What has been estimated so far, has been in the context of EU raw material security (Carrara et al., 2023).

Sustainability of Supply

Until 2200, a cumulative amount of about 443,000 tons of indium is demanded, but only 125,000 tons will be supplied from the extraction industry. The part of supply that comes from extraction is about 83,000 tons. The difference between extraction and supply is estimated to come from recycling. Thus, predicted indium supply will be about 26% of the indium demand. This deficit will transfer to photovoltaic capacity provision. This is supported by other studies (Michaux, 2019, 2021a, 2021b, 2021c).

In the discussion of sustainability, we should note that recycling can delay symptoms of scarcity for a significant time even after the primary production from mines has stopped. Only a part of the indium present in mother metals will be extracted and will be available for use. The potential that is not utilized is normally lost. Figure 8c shows the simulated supply per person and year and the indium stocks-in-use per capita. The dependent metals may fast run into physical scarcity because the price has no feedback on the extraction rate of copper, zinc or lead extraction rates. It is important to consider that, when the commodity is still relatively cheap, it may for that reason be wasted unnecessarily when it would, in retrospect, have been relatively easy to induce better use efficiency and recycling. The whole situation is balancing on a narrow edge, being dependent on recycling to take place driven by price alone.

The European Commission proposal has proposed a Critical Raw Material Act in 2023 that outlines a detailed strategy aimed at guaranteeing a secure and sustainable provision of essential raw materials to support the EU’s green and digital transformation efforts (European Commission, 2023). The purpose of the Critical Raw Material Act is to alleviate the potential of severe scarcity that would hamper optimal mitigation as strategies because the room of maneuver would be already missed. For a transition toward an energy-sustainable Europe, indium plays an important role in enabling the production of a range of sustainable technologies including solar panels, LED lighting, and high-tech electronic products (e.g.,, LED and LCD panel displays, Carrara et al., 2023). Thus, both energy-saving technologies and energy production technologies are at risk. For self-sufficiency and risk resilience, it is important to identify where in Europe indium sources would be located in the future, as easy accessible and potential later sites to be exploited. Currently identified sites in Europe reside in countries that already host mines that can be utilized to extract indium, such as Sweden, Poland, Portugal and Spain (EC 2017). Although there is no immediate scarcity of indium in the near future, putting infrastructure in place in Europe for future internal demand has a lag-time of decades regardless of any pathways chosen toward sustainable Europe in 2050.

Indium and Demand from New Photovoltaic Devices: A Small Sensitivity Analysis

Indium is a key element for making photovoltaic solar panels (Tables 1 and 2). In principle, the transition toward lower carbon-emitting electricity implies that we would like to make as many solar panels as possible. In the WORLD7 model, we estimated this number using Eq. 3, and considering indium, gallium and silver. Our estimate of possible installed production capacity made it clear that a large scale transition to photovoltaic panels will only be able to replace a fraction of the missing production capacity following a phase-out of fossil fuels. More efficient use of indium and better recycling may improve the situation marginally. Figures 13 and 14 show the results from a very simple sensitivity analysis in a number of diagrams. The sensitivity analysis was set up as follows: In the WORLD7 energy module, the photovoltaic installation indium demand was scaled up four times in four steps above the business-as-usual (Figs. 13a and 14a). The demand in indium amount results in an indium modified demand (Figure 13b).

Results from a simplified sensitivity analysis: (a) and (b) shows how the demand in (a) and the price-modified demand in (b) was scaled up from the reference case; (c) shows installed capacity of solar panels demanding indium. This is far below the photovoltaic installed power demand. (d) Shows change in supply as a response to increased indium demand. Since indium is a secondary extraction product from copper, zinc and lead mining, increased demand for indium has almost no effect on the copper, zinc and lead mining rates. All the lines have the same number connecting back to Figure 11a. Thus, demand line number 1 gives supply line 1 and price line 1 and installed effect line 1. Line 2 is business-as-usual

The system delivers an indium supply (Figure 13c) resulting in an installed photovoltaic collection capacity (Figure 13d). Comparing the curves in Figure 13b, d indicate what is going on: how the indium supply falls short of the indium demand by a huge amount. The demand for indium is satisfied until about 2024–2026. After then, photovoltaic demand for indium will increase more than indium supply, and there will be shortage of indium for photovoltaic panels. Only a modest fraction of the photovoltaic demand for indium can be satisfied (Figure 13a, b). We assumed a steady technical improvement over time from 2000 to 2060 (Figure 13c). Figure 13f shows the indium price, the pattern is one of continuous increase, caused by a steadily tightening indium market. During the period, the scarcity moves from soft scarcity (“less can be afforded”, and indium demand is adjusted down) to hard scarcity (“the shop is empty”). The indium price does increase enough to increase the indium recycling some, but yields limitations prevail. The result shows that the photovoltaic capacity demanded is far larger than what can be realized in reality. It appears to be not enough indium available. Figure 14b shows the simulation results for fulfilment of indium supply to photovoltaic production. Figure 14c shows the indium supply is unable to satisfy the indium demand for installed photovoltaic panel capacity based on indium. Figure 6b shows tons of indium used per GW installed photovoltaic panel; this is a curve we assumed in the simulations. If these technical improvements do not substantiate, then the result will be less installed photovoltaic capacity of the type dependent on indium. The rate of photovoltaic indium technology is slower than the demand, suggesting that the transition to solar electricity cannot be done on time as planned. By 2050, less than half the capacity planned will have been installed.

The Role of Policy Adaptation and Improving Circularity

It is important to note that there is no feedback from the indium system and back into the base metal mining (copper, zinc, lead, silver), see Figure 5. That implies that, regardless of the indium price, the volume of indium in the zinc produced is so small that it is insignificant to the cash flow of the zinc producer. If the indium extraction must be increased, a policy intervention is needed to incentivize price as well as fiscal and regulatory instruments to protect against unfair competition and price dumping tactics by external agents and producers. The implication is that an increase in the global indium production must be facilitated by EU policy intervention based on long term strategic decisions as outlined by the EU Critical Raw Material Act. Policy passivity in the indium market will not solve the problem.

Circularity does not alone solve the predicament of indium supply, but it will help on the way. A combination of indium supply management and indium demand management will be required, as well as management of yields and efficiencies. At present, indium recycling rates are low (most studies guess it to be in the order of 15–25%). Some of the present uses of indium as grain stabilizer in alloys, and in LED lighting, is difficult to recover and require substantial amounts of energy, and the indium recovery yields are low at present (2023).

Some adaptation measures are thinkable. Raising recovery and recycling to 50–60% would help a lot and could potentially double the future indium-dependent photovoltaic capacity by reducing indium losses, but they come at a high price in energy and efforts. Policies needs to be developed, so that the indium is only used in places where it can be recovered with a reasonable high degree of success (> 60%). Different proposals must be explored such as to put a deposit on it that can be earned by the recycler. How this can be done remains to be developed, considering technical, social and legal aspects and what kind od of measures that would be available on a national scale and more important, on an European scale.

European Dependency and Political Strategy toward a Desired Future

For many technology metals, Europe is dependent on imports today for pure metals, and there is some, but limited recycling capacity. Strategically, this is a position with limited negotiating power. For extraction of indium, China has a very dominant position today, and many countries have made themselves dependent on China for their strategic supply (Föst & Goldmann, 2021). An increasing amount of the indium extracted in China originate from ores imported to China for refining there, as well as refining wastes sold to China for refining there (Lin et al., 2021). It would and should be possibly to do this in Europe for the European waste. The experience from the rare earth elements sector, for what happened in the magnesium industry many decades ago, or photovoltaic panels would indicate that we must learn from the past and plan for better supply security and independence. A policy of greater self-sufficiency for Europe should be contemplated, to have an indium supply independent of external political forces.

This insight holds significant importance when designing strategies for sourcing raw materials for the various EU 2050 scenarios. The impending scarcity of indium, especially considering its crucial role in photovoltaic solar panels, highlights the pressing need to integrate sustainable metal strategies into the envisioned EU 2050 Imaginaries. It becomes essential to lay the groundwork for indium extraction, recycling, and conservation to support the development future sustainability pathways. Each imaginary, driven by its distinct vision, will demand customized policy pathways that can be summarized in general terms as follows:

-

1.

Ecotopia With focus on nature and reduced consumption, indium scarcity can be mitigated partially. However, community-driven solutions would likely push for improved recycling infrastructure and alternative energy sources that do not rely on indium. However, it is not only about indium, but also cobalt, germanium, gallium, tellurium, selenium and silver must be factored in. Limitations in these metals may set limits for electrification all machinery or how much solar panels that can be built.

-

2.

The Great Decoupling In a world driven by technological advances, indium shortage may catalyze innovations in alternative technologies. Given the emphasis on green growth, government intervention will be necessary to bolster indium recycling and manage its consumption more efficiently than at present. The great decoupling hinges heavy in the notion that green growth and global decoupling is possible. So far, that remains unproven.

-

3.

Unity in Adversity A unified Europe would proactively address indium scarcity through investments in recycling infrastructure and comprehensive policies to secure the supply of essential metals. The potential for metal tracking and tracing system would be needed to be developed, to secure proper accounting. This will need to solve how a race-on-resources will be avoided and how cooperation is secured in a competitive environment.

-

4.

Technocracy for the Common Good Under strong state control, strategies for improving indium extraction and recycling would be rigorously implemented. The focus might shift toward internal, sustainable practices to counteract indium scarcity. How this will be done within the framework of democracy will be decisive for whether this can be achieved. The issue of trust capital stocks, production and loss in society will be decisive if this can go well.

In their present states, the imaginaries are largely principal and conceptual. Each imaginary includes metals and minerals but varies in its approach to production, usage, and circularity concepts. The imaginaries presented illustrate different sustainable futures, each following a unique path that differs from the present. Although these futures are hypothetical and do not currently exist, they can serve as a tool for identifying the steps and strategies needed to create a sustainable future. All of these must be developed further with integrated assessment modeling to quantitative simulations with respect to production, usage, circularity concepts and sustainability. For each, a number of fundamental assumptions must be made and evaluated against the final outcomes. The social dimension of the imaginaries remains to be worked out and understood, before any plan can be made (O’Brien, 2017). The historical experience in European history with top-down strong state control has been characterized by negative outcomes (Implied in 4. Technocracy for the common good), and there is still need for a credible explanation of how such system can curb power abuse and corruption. See the works of Tainter (1996; 2008; 1988, 1995), Tilly (2005, 2006, 2007) and O’Brien (2017) for some fundamental discussions on this issue.

In a broader sense, up to now, decoupling never really took place anywhere, it has only shifted the burden around from one country to the other. The largest shifting thus far was by off-shoring and moving production to China and low-cost countries (van Allen et al., 2022). In order for imaginaries number 2 and number 4 to become true to reality, one paradigm pattern must be broken: up to now, every energy-saving and any increase in resource use efficiency has not been saved or resulted in lower consumption. To the contrary, the potential energy gains and materials savings made so far, were rolled forward into more consumption. Thus, the improved efficiencies did not slow down consumption or waste, total consumption was accelerated and grew more instead. This was discussed by van Allen et al. (2022) in the context of seeing the thermodynamic limitations of the concept of circularity, and the lack of any sign of decoupling being something that actually works. For earlier discussions on the same theme, see Bringezu et al. (2004), York and McGee (2015), Zhang et al. (2016) and Fletcher and Rammelt (2017).

As van Allen et al. (2022) showed, as many others did several times before them, economic growth has so far been hard-linked to growth in resource use, and there is no nationwide example of how to break it so far. Contrary, everything points toward the hard-linking of economic wealth production to natural resources conversion becoming stronger. On a higher level, the key question that must be asked is if supply is insufficient or demand too high? Is a paradigm of perpetual economic growth the solution to the problem or the root cause of the problem? (Heinberg, 2011). And, demand is linked to population and stability of society, an issue often avoided (Tainter, 1988, 1995, 1996, 2008; O’Sullivan, 2023). This points out that the EU Imaginaries are initiators in an iterative adaptive learning process assisted by integrated assessment models, making sure all steps and the end states are sustainable.

Conclusions

The WORLD7 model was used to simulate the indium extraction rates and approximate metal price levels as observed by the available data. The model works for reconstructing the extraction and price patterns of the past. The simulations show that the rate of recycling is far too low for indium, and the indium supply situation may be significantly improved if the indium recycling rates can be increased. Of the indium present in mother metals, estimated to be about 550,000 tons indium, we estimated that total of about 310,000 tons indium will be extracted under business-as-usual. The introduction of extraction methods like heap leaching and subsequent electrowinning for many of the source metals (copper, zinc, lead) will yield less of indium and it is a real threat to the long term supply of indium. These methods are preferred for low and ultralow ores grades and have become more frequent in mining. A small sensitivity analysis, tested what would happen if the demand increased by 100%, 200%, 300% or 400%, indicated that the peak production would come somewhat earlier, increasing supply somewhat, but in no way in the amounts needed to satisfy even the level of the present demand. Thus, the future shortage appears as serious and not possible to mitigate by digging more now and faster. It just implies burning off the available resource faster, leaving future generations without indium altogether. Sustainability is defined for both the present and future generations. And, the future generations are many (Brandon Carter, 1983; Leslie, 1998).

Much potential indium production opportunity is lost because of lack of technical infrastructure to extract indium at zinc, lead, copper and silver metal refineries. The indium potential in mined base metals that is not extracted, is lost at the rate of the base metal mining. Thus, the potential declines over time, also when the indium potential is not harvested. For a time after primary metal mining has been reduced to insignificant levels, the indium supply may be kept up by efficient recycling for a while. So far, market mechanisms have not been able to have sufficient effect on indium circularity, and it appears that additional governmental actions will be required. The conclusion is that there is an immediate risk for scarcity for indium. In the longer run (after 2040), scarcity will be manifested as rising metal prices and physical scarcity should be expected and prepared for. Much depend on how the demand will develop, and further integrated assessments will be required to analyze the full consequences and outline what kind of indium management plans that should be made.

Indium production will peak in 2025–2030 and photovoltaic solar panels are expected to peak in 2090 at about 1200 GW installed effect because of lack of indium. The building of photovoltaic capacity will run at a lower speed than demand indicates, potentially delaying the transition to renewable energy sources. In the wider relation to different pathways toward sustainability, the results showcase the importance of preparing infrastructure for indium extraction, recycling and conservation and other rare minerals for alternative pathways of sustainable Europe 2050 imaginaries. Improving recycling will take time as the infrastructure is partly missing. This is reflected in the increase in recycling shown in Figure 12e.

Additional work would be to develop the conditions and the scenarios further. Crystalline silicon photovoltaic cell panels without indium are possible, but they have lower conversion efficiency, and they still use silver. Combination with other solar panel types making the grand puzzle of many scarce metals should be explored using the WORLD7 model or something similar.

The Imaginaries, with their reliance on natural resources like indium and other technology metals, underscore the need to address systemic challenges of today and finding the way to bridge the gap to achieve the envisioned Imaginaries. This underlines the need for integrated assessment models to test “what-if”, finding optimal policy options for specific Imaginaries. In the context of a longer development process, the present four imaginaries will be tested for viability and plausibility in terms of critical metal circularity, as an element of understanding their specific robustness and resilience in terms of internal and external shocks. This is all part of an adaptive, innovative learning process (Senge, 1990; Senge et al., 2008).

References

Alfantazi, A. M., & Moskalyk, R. R. (2003). Processing of indium: A review. Minerals Engineering, 16, 687–694.

Almosni, S., Delamarre, A., Jehl, Z., Suchet, D., Cojocaru, L., Giteau, M., Behaghel, B., Julian, A., Ibrahim, C., Tatry, L., & Wang, H. (2018). Material challenges for solar cells in the twenty-first century: Directions in emerging technologies. Science and Technology of Advanced Materials, 19(1), 336–369.

Alonso, E., Frankfield, J. G., & Kirchhain, R. (2007). Material availability and the supply chain, risks, effects, and responses. Environmental Science and Technology, 41, 6649–6656.

Bardi, U. (2013). Extracted: How the quest for mineral wealth is plundering the planet. The past, present and future of global mineral depletion. A report to the Club of Rome (p. 299). Chelsa Green Publishing.

Bleiwas, D. I. (2010). By-product mineral commodities used for the production of photovoltaic cells. Circular 1365, United States Geological Survey.

Brandon Carter, W. H. (1983). The anthropic principle and its implications for biological evolution. Philosophical Transactions of the Royal Society of London A, 310(1512), 347–363.

Bringezu, S., Schütz, H., Steger, S., & Baudisch, J. (2004). International comparison of resource use and its relation to economic growth. Ecological Economics, 51, 97–124.

Briskey, J. A. (2005). Indium in zinc-lead and other mineral deposits: A reconnaissance survey of 1118 indium analyzes published before 1985. United States Geological Survey, Mineral Resources Program—Eastern Mineral Resources Team. Open-File Report 2005–1209

Brown, T. J., Wrighton, C. E., Raycraft, E. R., Shaw, R. A., Deady, E. A., Rippingale, J., Bide, T., & Idoine, N. (2015). World mineral production 2009–2013 (p. 88). British Geological Survey.

Busch, J., Steinberger, J. K., Dawson, D. A., Purnell, P., & Roelich, K. (2014). Managing critical materials with a technology-specific stocks and flows model. Environmental Science and Technology, 48, 1298–1305.

Candelise, C., Winskel, M., & Gross, R. (2012). Implications for CdTe and CIGS technologies production costs of indium and tellurium scarcity. Progress in Photovoltaics Research and Applications, 20, 816–831.

Carrara, S., Bobba, S., Blagoeva, D., Alves Dias, P., Cavalli, A., Georgitzikis, K., Grohol, M., Itul, A., Kuzov, T., Latunussa, C., Lyons, L., Malano, G., Maury, T., Prior Arce, A., Somers, J., Telsnig, T., Veeh, C., Wittmer, D., Black, C., … Christou, M. (2023). Supply chain analysis and material demand forecast in strategic technologies and sectors in the EU: A foresight study. Publications Office of the European Union. https://doi.org/10.2760/334074

Cesaro, A., Marra, A., Kuchta, K., Belgiorno, V., & van Hullebusch, E. D. (2018). WEEE management in a circular economy perspective: An overview. Global NEST Journal, 20, 743–750.

Choi, C. H., Cao, J., & Zhaio, F. (2016). System dynamics Modeling of indium material flows under wide deployment of clean energy technologies. Resources, Conservation and Recycling, 114, 59–71.

Critical Raw Material Act. (2023). European commission, “Proposal for a regulation of the European parliament and of the council establishing a framework for ensuring a secure and sustainable supply of critical raw materials”. COM(2023) 160 final, 2023/09/14, available at, https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX, 52023PC0160.

Cucchiella, F., D’Adamo, I., Lenny Koh, S. C., & Rosa, P. (2015). Recycling of WEEEs: An economic assessment of present and future e-waste streams. Renewable and Sustainable Energy Reviews, 51, 263–272.

Dahmus, J. B., & Gutowski, T. G. (2007). What gets recycled: An information theory based model for product recycling. Environmental Science and Technology, 41, 7543–7550.

Davidsson, S., & Höök, M. (2017). Material requirements and availability for multi-terawatt deployment of photovoltaics. Energy Policy, 108, 574–582. https://doi.org/10.1016/j.enpol.2017.06.028

Demarthe, J. M., Rousseau, A. M., & Fernandez, F. L. (1990). Recovery of specialty metals, mainly germanium and indium, from zinc primary smelting. In Lead-Zinc ‘90, Anaheim, Calif., February 18–21, 1990, Proceedings, Warrendale, Pa., The Minerals, Metals & Materials Society (pp. 151–160).

Drzaga, M., Palmowski, A., Benke, G., Ciszewaski, M., & Leszczynska-Sedja, K. (2021). Recovery of germanium and indium from leaching solution of germanium dross using solvent extraction with TOA, TBP and D2EHPA. Hydrometalurgy, 202, 105605.

EEA. (2022). EEA imagining sustainable futures for Europe in 2050. A co-creation project of the EEA and its country network Eionet: The need for fundamental change available online, https://www.eea.europa.eu/publications/scenarios-for-a-sustainable-europe-2050

Elshkaki, A., & Graedel, T. E. (2013). Dynamic analysis of the global metals flows and stocks in electricity generation technologies. Journal of Cleaner Production, 59, 260–273.

Elshkaki, A., & Graedel, T. E. (2015). Solar cell metals and their hosts: A tale of oversupply and undersupply. Applied Energy, 158, 167–177.

European Commission. (2017). Study on the review of the list of critical raw materials. https://op.europa.eu/en/publication-detail/-/publication/33a9974e-e14b-11e6-ba9a-01aa75ed71a1

Flanagan, D. M. (2023). Copper. https://pubs.usgs.gov/periodicals/mcs2022/mcs2022-copper.pdf

Fletcher, R., & Rammelt, C. (2017). Decoupling: A key fantasy of the post-2015 sustainable development agenda. Globalizations, 14, 450–467.